Introduction to Lean Logistics

The Lean Logistic concept is part and parcel of experiencing your business unfold before your eyes. Setting up deliverables and supply chain with Lean Logistics for business efficiency. Lean Logistics looks at reducing the waste that is created at all checkpoints along the supply chain and uses the concepts of Lean to eliminate these wastes under clear supervision and process improvement efforts.

Lean Logistic

What are businesses made of? What are the main components of a business? How important is profit to your business? Where can you make the cut and elevate your business to achieve the targets you set? What do businesses require? We all know the answers to these questions deep down in our minds. Incorporating successful techniques and frameworks for desired business outcomes. Whether you’re an entrepreneur or a project manager contributing to a small- or large-scale business, it comes down to how you open Pandora’s Box and unleash all the needed methods to get those ROIs ringing in for your business.

Businesses are essentially made up of valued and hard-working employees collaborating to indulge in investments and gather enough customers to render goods, products, or services that will be exchanged to make a profit. Companies invest in logistics strategies to enhance product catalogs and increase throughput.

“More from Less”: Mantra for enhancing supply chain with waste elimination strategies. This increases productivity and causes a reduction in processing time and complete utilization of available space and resources. Companies nowadays are going “Lean”.

What is Lean Logistics?

The attributes and principles mentioned above are the basic fundamentals of Lean Logistics. We will dive into this before heading to what Lean Logistics can do for your business and how.

Businesses strive for a competitive edge by pushing boundaries and gaining industry advantage. Reducing time, costs, and inventory seems to crop up as the needs of the hour for businesses to achieve maximum success.

Cutting the chase to understand Lean Logistics, you can effectively describe it as an efficient way to recognize and eliminate activities that appear wasteful in the supply chain to increase the product flow and the speed at which the product is belted out.

Logistics Management is a key component in any business, manufacturing, or production setup. This phase of the supply chain manages product flow through planning, implementation, monitoring, and control for optimal efficiency. Be it the forward or reverse flow of these goods and products and services, from the point of origin of these entities to the point of consumption, that is, the customers, adding a pinch of Lean Manufacturing concepts within this and, bingo! You have a winning formula at hand.

Each step taken in Lean Logistics aims at making the qualitative separation of processes into value-adding and non-value-adding processes within the supply chain, with a view to eliminating all the non-value-adding processes. Contributing to this aspect of the introduction of Lean Logistics is its driving factor, Lean thinking. Let’s have a quick sneak peek into what lean thinking is in the next section.

Lean Thinking

To completely implement Lean Logistics, Lean thinking should be a major part of your planning, implementing, and controlling phases. At each point, you will need to think about making process choices in the direction of Lean. Organizations that employ Lean thinking within their supply chain workflows have noticed considerable benefits reaped from the move. Customer service quality increased manifold, and the environmental impact of the reduction in waste was highly magnified. It even improved their corporate citizenship in the long run.

Lean Logistics evolved from Japanese manufacturing methods, incorporating Lean thinking to optimize the supply chain. With minimal resources and timelines given to production units and further on to internal and external logistics, Lean thinking made it possible to eliminate wastes considerably, ushering in the best practices for when in a crunched resource/time situation.

Lean thinking aims for perfection by continuously measuring and reducing waste throughout the supply chain. Thus, reinstating complete product value. This would also mean customers wouldn’t pay for the excess you lost due to elaborate waste along the supply line. Reducing the total overall cost made customers happy. In turn, the business grew, making it possible for customers to purchase the products and reckon for their high quality.

Principles of Lean Thinking

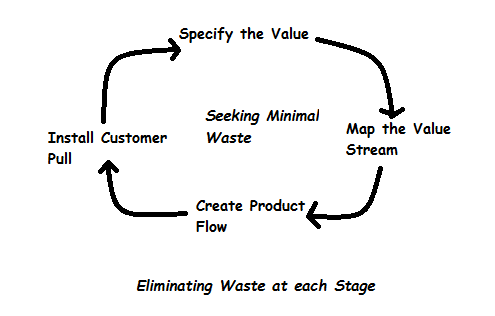

Applying the four principles of Lean thinking in Lean Logistics results in minimal waste. They are as follows:

- Specifying the Value – This primary task is to specify and distribute the customer-required value with the supply chain network. Lean Logistics focuses on understanding customer needs and optimizing processes to meet those needs while ensuring profitability.

- Mapping out the Value Stream of the Supply Chain – Once you know the value you seek, map the workflow along the supply chain and check if there are non-value-adding processes in the stream. With this knowledge, you can eliminate redundant, non-productive processes and save on equivalent time and resources, thus boosting your lead time and reducing excessive costs. Hold the stream against the value specified by customers and check again. This way, you will know how close you are to the value your customers need and where there is a further deviation or wastage.

- Creating a Product Flow – Here, you can jot down a supply chain workflow devoid of any process loops or interruptions, downtimes, or inventories. You will now have a smooth process at hand in the paradigm of Lean Logistics.

- Luring Customers for a Long Stay – Enable manufacturing only per customer demand. This will imply that demand information is clear through the supply chain.

Affecting the Business Bottom Line

Managing your lean logistics and supply chain is essential for those business graphs to skyrocket. Logistics, often plagued by legacy issues, remains a significant business challenge. But, with recent methodologies invading the logistics and supply chain, it’s becoming easier for managers to adopt such tools and techniques under the Lean Logistics paradigm to reduce waste and increase process performance. Let’s dive into how you can affect your business through Lean Logistics and what you need to be keeping a careful eye on while implementing this world-famous technique.

Incorporating the Concept

While we know what Lean Logistics is and have our fingers wrapped around Lean thinking, all we need to do now is incorporate this concept into your supply chain. Doing so will help you meet market standards and customer demands on time and produce the least or no waste. This mostly affects the transportation process when it comes to logistics.

Applying Lean Logistics has prompted managers to look beyond transporting goods from point A to point B. With the implementation of Lean Logistics, managers are looking at the complete utilization of resources and space and have even seen a reduction in time spent on transportation. All these while still adhering to timely deliveries to point B.

Image source: pixabay.comAn early technique used by Lean Logistics is the one called “Milk Run”. This would mean gathering goods from multiple locations while on a single trip to that point B, thus, in an effort to utilize complete space and save on fuel costs.

For a manager to incorporate this framework of Lean Logistics, they need to pay attention to the following statements:

- The logistics unit of the organization incorporates Lean Logistics as a regular work culture on a daily basis.

- To save on the supply chain, it’s crucial to monitor and reduce waste in all processes diligently.

- Lean Logistics involves team collaboration to identify and implement changes to achieve the desired state.

- You need to do your research, such as searching “courier services near me” on Google, to find reliable third-party businesses that can supercharge your supply chain.

- Team members need to be educated about Lean Logistics, Lean thinking, and what the framework aims at

- Look at the big picture always; your customer needs to be fulfilled.

- When initiating the implementation, ensure that you target the simple areas first and slowly progress through the chain.

Adapting to Changes

People are reluctant to change; this fact has been tagging with industries for centuries. But, with change comes the part of evolution and making things better. Organizations are in a bid to overcome this fear of change and implement Lean Logistics to better institutionalize the concept of change for the better among their employees.

Image source: pixabay.comClients restrict change as they feel unsure about removing any steps within the supply chain. In such cases, a mutual presentation needs to be put in front of the client to make them understand the concepts of Lean Logistics and how it will benefit the company with its implementation. Organizing workshops and meeting sessions can boost the knowledge of your clients and employees working the changeup.

Little Details

Throughout the supply chain, every detail is peculiar and extremely important. Whether it is a small printing operation or even the labeling on a box, each detail needs to be magnified to see a qualitative picture at the end of the line. Or, take the printing of the box seal, checking for the orientation of the paper that would conserve more space, thus, saving more paper for doubling its use in the process. Even the placement of equipment should be well-thought-of in order to conserve time and effort spent on them. Wrong placement can lead to added time to the completion of the activity. Lean Logistics is based on the premise of considering everything in the process.

Image source: pixabay.comA manager requires a holistic understanding of the business’s goals to delve into the details of Lean Logistics. In Lean Logistics, a clear strategy is crucial to identify wasteful steps and eliminate them. In the same way, in order to get a view of these details, one has to know the business and the process leading to logistics inside-out. This will have a greater impact on adopting Lean Logistics and facilitate a healthier implementation among the business, thus, improving it at all times.

Mind Culture

Each company is different, with different work culture and different processes. Even approaching changes and systems is different for every organization. Inculcating the principles of Lean Logistics needs to affect these areas, but since they are peculiar to the organization, Lean needs to have a buy-in. To address the significant differences that exist from one company to another, Lean Logistics must be implemented in a systematic and logical manner without relying on reference points for direct replication.

Image source: pixabay.comThe ways of Lean are meticulous and need a clear thought process, not only by the manager, who is orchestrating the entire implementation, but also by the team members handling the equipment and driving the process. Setting a proper mindset is needed at every level of the supply chain for Lean-to to succeed in all its efforts. And this mindset can percolate through thorough training, coaching, and mentoring.