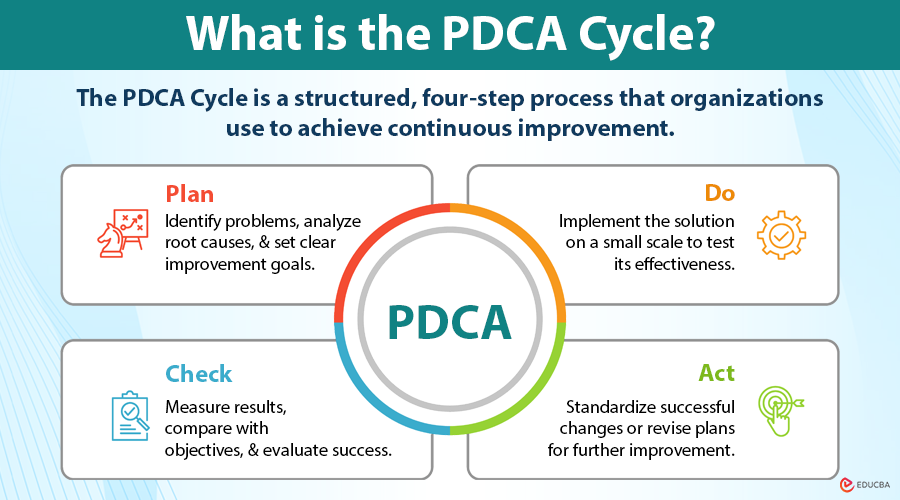

What is the PDCA Cycle?

The PDCA Cycle is a structured, four-step process that organizations use to achieve continuous improvement. Each stage builds on the previous one and creates a feedback loop where teams test improvements, measure results, and institutionalize successful changes.

The PDCA cycle originated in the 1930s with Walter A. Shewhart, often called the “father of statistical quality control.” Later, W. Edwards Deming refined and popularized the approach during post-World War II reconstruction in Japan, helping Japanese companies like Toyota establish themselves as global leaders in quality management.

The PDCA Cycle is applied worldwide across manufacturing, services, government, education, and healthcare. Its versatility lies in its simplicity: regardless of industry or scale, organizations can follow the same four steps to manage change systematically.

Table of Contents

- What is the PDCA Cycle?

- The Four Steps of the PDCA Cycle

- Benefits of the PDCA Cycle

- Applications of the PDCA Cycle

- PDCA vs. Other Improvement Models

- Challenges and Limitations

The Four Steps of the PDCA Cycle

1. Plan – Building the Foundation

The Plan phase involves identifying areas for improvement and developing a strategy to address them. Planning is critical because the quality of execution depends heavily on the quality of preparation.

Key activities in this stage include:

- Problem identification: Recognize inefficiencies, bottlenecks, or opportunities. This could be rising customer complaints, declining productivity, or new regulatory requirements.

- Data collection & analysis: Gather historical performance data, customer feedback, and process insights to understand the current situation.

- Root cause analysis: Use quality tools like the Ishikawa (Fishbone) Diagram, Pareto Analysis, or 5 Whys to uncover underlying causes rather than just symptoms.

- Setting SMART goals: Set clear goals that are realistic, measurable, relevant, and have a deadline.

- Developing hypotheses & plans: Brainstorm possible solutions, evaluate alternatives, and select the most feasible plan.

The goal is set: reduce patient wait times by 25% in the next two months.

2. Do – Implementing the Change

The Do phase involves implementing the planned change on a small scale. This reduces risks and allows organizations to test whether the proposed solution works in real-world conditions.

Key activities in this stage include:

- Pilot testing: Apply the solution in one department, team, or location before scaling it organization-wide.

- Employee training: Ensure staff understand new responsibilities, procedures, or tools.

- Documentation: Record steps, challenges, and feedback during the trial period.

- Data collection: Monitor performance indicators to evaluate outcomes later.

Best Practices:

- Keep the scope small to minimize disruption.

- Involve frontline employees to get practical insights.

- Track unintended consequences, not just expected outcomes.

3. Check – Measuring and Evaluating Results

The Check phase is about analyzing whether the implemented changes delivered the expected results. It is the learning phase of the cycle, where organizations gain insights from data.

Key activities in this stage include:

- Performance measurement: Compare actual results with the goals set in the Plan phase.

- Gap analysis: Identify differences between expected and actual outcomes.

- Qualitative feedback: Collect employee and customer input to gain context behind the numbers.

- Root cause verification: Confirm whether the change addressed the root cause or if further action is required.

Best Practices:

- Use both quantitative metrics (defect rates, waiting times, costs) and qualitative observations (employee morale, customer feedback).

- Be objective, avoid justifying the plan if it did not work.

4. Act – Standardizing and Scaling

The Act phase determines whether the change should be adopted, adjusted, or abandoned. If the improvement succeeds, the organization standardizes it. If it fails, the team uses the lessons learned to design a new plan and continue the cycle.

Key activities in this stage include:

- Standardization: Document new processes in manuals, SOPs, or guidelines.

- Training & rollout: Train employees organization-wide to apply the improved process.

- Continuous monitoring: Establish performance indicators to sustain improvements.

- Iteration: If results are unsatisfactory, return to the Plan stage with new insights.

Benefits of the PDCA Cycle

The PDCA Cycle offers numerous advantages, which explain its widespread adoption:

- Simplicity & clarity: Easy to understand and apply across industries.

- Continuous learning: Encourages organizations to keep experimenting and learning from mistakes.

- Risk mitigation: Trying changes on a small scale helps avoid expensive mistakes.

- Data-driven decision making: The PDCA Cycle bases decisions on evidence rather than assumptions.

- Employee empowerment: Engages staff in identifying problems and creating solutions.

- Customer focus: Enables organizations to respond more effectively to customer needs.

- Scalability: Works for small teams as well as large corporations.

Applications of the PDCA Cycle

The versatility of PDCA makes it useful across industries and functions:

- Manufacturing: Improving product quality, reducing waste, and enhancing production efficiency.

- Healthcare: Reducing medical errors, optimizing patient flow, and improving safety protocols.

- Education: Developing teaching strategies, assessing student outcomes, and refining curricula.

- IT & software: Iterative testing in Agile or DevOps projects, improving system performance.

- Public sector: Policy testing, service delivery improvements, and regulatory compliance.

- Business strategy: Market testing, customer service enhancements, and operational efficiency.

PDCA vs. Other Improvement Models

- PDCA vs. PDSA (Plan-Do-Study-Act): PDSA emphasizes deeper reflection in the “Study” stage, making it more research-oriented, whereas PDCA is broader and often faster in application.

- PDCA vs. DMAIC (Six Sigma): DMAIC is more data-intensive and structured, often requiring statistical analysis, while PDCA is flexible and simpler for everyday improvements.

- PDCA vs. Kaizen: Kaizen is a cultural philosophy of small, incremental improvements, while PDCA provides a structured method to implement Kaizen initiatives.

Challenges and Limitations

Despite its strengths, organizations may face difficulties when using PDCA:

- Cultural resistance: Employees may resist changes or view continuous improvement as extra work.

- Time investment: Repeated cycles can be time-consuming, especially in fast-paced industries.

- Data quality issues: Poor data collection can lead to wrong conclusions in the “Check” stage.

- Misapplication: Treating PDCA as a one-off project instead of a continuous cycle reduces effectiveness.

Overcoming these challenges requires leadership support, clear communication, and a commitment to organizational learning.

Final Thoughts

The PDCA Cycle is more than a quality management tool; it is a philosophy of continuous improvement. By following its four steps, Plan, Do, Check, Act, organizations can solve problems systematically, reduce risks, and foster innovation.

Its success lies not in a single cycle but in repetition. Each cycle builds on the last, helping teams learn, adjust, and improve processes. When embraced as part of organizational culture, PDCA becomes a powerful engine of growth, efficiency, and resilience in a competitive world.

Frequently Asked Questions (FAQs)

Q1. Can PDCA be combined with other methodologies?

Answer: Yes. Many organizations integrate PDCA with Lean, Six Sigma, Agile, or Kaizen. For example, Agile software teams use PDCA within sprint reviews and retrospectives.

Q2. How does PDCA support innovation, not just quality control?

Answer: PDCA is not limited to fixing problems. Teams can use it to test new ideas, pilot products, or explore business models in a structured, low-risk way.

Q3. What tools can support the PDCA Cycle?

Answer: Organizations often use tools like SWOT Analysis, Balanced Scorecards, Gantt Charts, and project management software to plan and track PDCA activities more effectively.

Q4. How do leaders ensure PDCA does not lose momentum?

Answer: Leadership can sustain PDCA by setting clear KPIs, celebrating small wins, encouraging employee involvement, and embedding improvement cycles into regular workflows.

Recommended Articles

We hope this guide on the PDCA Cycle was helpful. Explore related articles on quality management, process improvement, and business strategies to drive continuous growth in your organization.