Updated May 30, 2023

What is Electrical Discharge Machining?

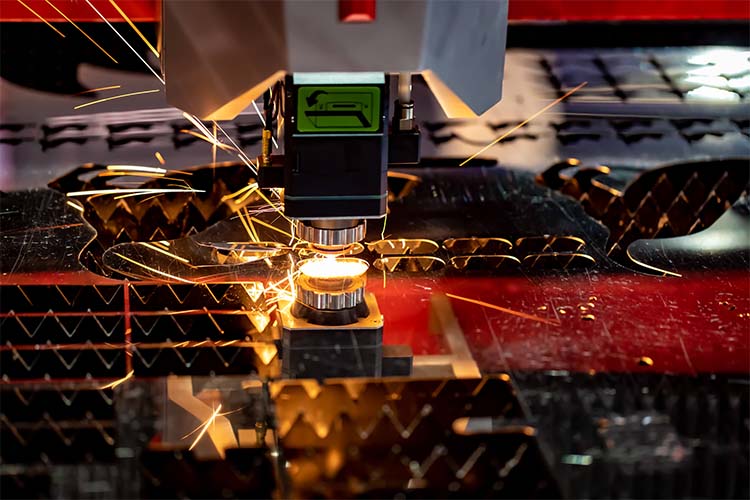

Electrical discharge machining refers to applying heat energy to remove excess material from a workpiece and creating the precise shape needed for a task. The procedure of EDM uses electrical discharge instead of mechanical force, eliminating the need for additional tools at work. EDM is often the best choice when creating complicated forms or working with durable materials like titanium.

Electrical Discharge Machining consists of two electrodes placed apart by a dielectric liquid, usually deionized water or oil. When the dielectric between the two electrodes breaks down, current flows through, expulsing material from both electrodes when the field strength between them is strong enough. The instantaneous current flow between the electrodes produces particular debris, which is not constant. The fluid flushes out that debris. Repeatedly performing this procedure to carve a workpiece is a precisely controlled feature that one cannot achieve with conventional machining techniques.

Types of EDM

Electrical Discharge Machining is of three types. They are wire EDM, hole drilling EDM, and sinker EDM.

1. Wire EDM

Wire EDMs, referred to as wire erosion, wire cutting, or EDN cutting, refer to a machining process using a conductive metallic wire to carve or shape a workpiece. The metallic wire often follows a carefully programmed path.

As there is no direct contact between the wire and the workpiece during the process, you can produce the material’s shape without altering the wire’s course. To do so, you charge the wire quickly to the desired voltage. Deionized water also surrounds the wire. A spark passes through the gap when the voltage is at the proper level, melting a small workpiece area. The deionized water cools and removes the debris from the void by flushing it out.

The workpiece material’s hardness has no negative impact on the cutting speed. Wire cutting is a typical procedure to manufacture extrusion dies and blanking punches.

2. Fast Hole Drilling EDM

Regardless of the material’s hardness, the design of the EDM hole driller creates semi-accurate holes at high speeds in ductile materials. Like other EDM operations, hole drilling EDM also uses dielectric fluid or flushing liquid to remove the cut’s eroded particles. Delivering the flushing liquid to the bottom of the cut hole is vital. It calls for a drilling electrode with a thru-hole or a tube to allow fluid to pass the electrode consistently and readily.

EDM hole drilling machines assist in carrying out various tasks, including simple hole drilling, retrieving broken tap, drill, and reamer bits, creating wire EDM holes, and cooling holes in aeronautical engine components. A few industries that could benefit from EDM drilling machines are aerospace, energy, general manufacturing, mold-making or repair, medicine, and healthcare.

3. Sinker EDM

Sinker EDM uses a copper or graphite electrode to shape the metal workpiece by melting away material from a workpiece. The procedure involves immersing the electrodes in a dielectric fluid. The dielectric fluid acts as an insulator until the machine attains a sufficiently high voltage. Without an insulator, this process would cause a short circuit.

The dielectric oil also serves as a coolant to remove heat from the component and limit excessive thermal expansion. A chiller keeps the oil below its flash point. In comparison, a filter is in charge of removing any metal fragments. In contrast, a sinker EDM works on any metal, regardless of its hardness.

Advantages of Electrical Discharge Machining

Here are a few advantages of using Electrical Discharge Machining:

- You can use it on any metal that conducts electricity.

- It enables the machining of even complex shapes.

- Electrical discharge machining takes less time than traditional machining methods.

- There is no mechanical tension, as there is no contact between the tool and the workpiece during the machining procedure.

- The procedure of EDM results in an excellent surface finish.

- EDM efficiently assists in creating small holes.

- It helps in machining delicate and thin workpieces with great precision.

- It helps eliminate the need for a heat treatment process.

- The workpiece requires little to no polishing after the completion of the procedure.

Recommended Articles

We hope that this EDUCBA information on “Electrical Discharge Machining” was beneficial to you. You can view EDUCBA’s recommended articles for more information,