What is a Digital Thread?

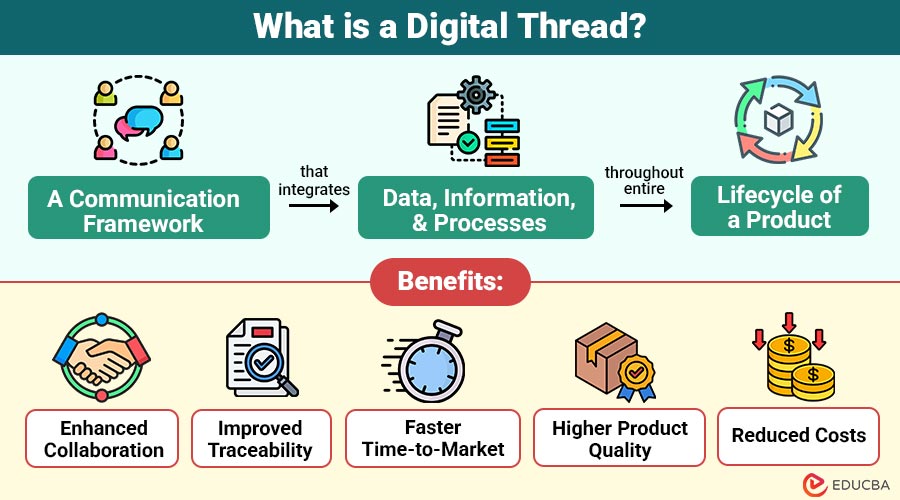

The Digital Thread is a communication framework that integrates data, information, and processes throughout the entire lifecycle of a product. It acts as a data backbone connecting design, engineering, manufacturing, quality assurance, and service, ensuring that all stakeholders have real-time access to consistent and accurate information.

Key Elements:

- End-to-End Connectivity: Links data from concept to decommission.

- Interoperability: Enables different systems, tools, and platforms to communicate seamlessly.

- Traceability: Maintains a complete record of design changes, production steps, and operational history.

- Real-Time Insights: Facilitates predictive analytics and proactive decision-making.

Table of Contents:

- Meaning

- Importance

- Benefits

- Key Technologies

- Use Cases

- Challenges

- Steps to Implement a Digital thread

- Real World Examples

- Future Trends

Key Takeaways:

- Digital Thread connects all product lifecycle stages, ensuring seamless, real-time data flow and collaboration.

- It enhances traceability, enabling compliance, quality control, and informed decision-making across teams and processes.

- Integration with IoT, AI, and cloud technologies boosts predictive capabilities and operational efficiency.

- Adoption challenges exist, but phased implementation and open standards improve feasibility for all business sizes.

Why is Digital Thread Important?

Without a digital thread, product information often remains trapped in silos, causing inefficiencies, delays, and errors. By providing a single source of truth, the digital thread:

1. Reduces Rework and Duplication of Effort

By ensuring all teams access the same accurate data, the digital thread eliminates redundant tasks and unnecessary mistakes.

2. Improves Quality and Compliance

Centralized, traceable product data ensures adherence to industry standards, reduces errors, and enhances product reliability across all development stages.

3. Shortens Development Cycles

Smooth sharing of information between teams helps decisions happen faster, avoids delays, and speeds up product design, testing, and launch—all while keeping quality and rules in check.

4. Enables Continuous Improvement

Real-time feedback loops and historical data analysis empower organizations to refine processes, optimize performance, and innovate effectively over product lifecycles.

Benefits of Implementing a Digital Thread

Here are the benefits organizations can achieve by adopting a robust strategy:

1. Enhanced Collaboration

By connecting engineering, manufacturing, and service teams with shared data, the digital thread removes communication barriers, improves coordination, and fosters unified decision-making across the organization.

2. Improved Traceability

Tracks every stage of a product’s lifecycle with complete data history, ensuring compliance, simplifying audits, and providing transparency for stakeholders, regulators, and internal quality management systems.

3. Faster Time-to-Market

Streamlined workflows and instant information access help eliminate bottlenecks, speed up approvals, and enable quicker product launches without compromising quality or regulatory compliance standards.

4. Higher Product Quality

Early issue detection through integrated quality data enables proactive problem-solving, reducing defects, enhancing reliability, and ensuring products consistently meet or exceed customer expectations.

5. Reduced Costs

It helps reduce waste and mistakes by using resources better, making processes smoother, and providing the right data on time to make smart decisions and plans.

Key Technologies Powering the Digital Thread

Here are the core technologies that enable the seamless integration, visibility, and efficiency of a digital thread:

1. Product Lifecycle Management Systems

Manage all product data, processes, and collaboration across teams to ensure consistent, accurate information throughout the lifecycle.

2. Internet of Things

Collects real-time operational data from connected devices, enabling monitoring, analysis, and optimization of product performance and usage.

3. Digital Twin

A dynamic virtual model of a physical product, enabling simulation, analysis, predictive insights, and performance optimization throughout its lifecycle.

4. Cloud Computing

Offers scalable storage, processing power, and remote accessibility, supporting collaboration, data sharing, and integration across distributed teams and systems globally.

5. AI & Machine Learning

Provide predictive maintenance, automated decision-making, and intelligent insights by analyzing historical and real-time data for process improvement.

6. Enterprise Resource Planning

Integrates business and operational processes, ensuring data consistency, streamlined workflows, and improved decision-making across all departments in an organization.

Use Cases of Digital Thread

Here are some of the most impactful industry applications where a digital thread drives efficiency, compliance, and innovation:

1. Manufacturing

Digital threads integrate CAD, PLM, ERP, and MES systems, enabling real-time visibility into production processes and ensuring product quality.

2. Aerospace and Defense

Tracks parts and assembly details across decades, ensuring regulatory compliance and improving maintenance planning.

3. Automotive

Connects design changes to manufacturing lines instantly, reducing delays and enabling mass customization.

4. Medical Devices

Ensures compliance with stringent regulations like FDA 21 CFR Part 11 by maintaining traceable documentation.

5. Energy Sector

Links operational data from power plants and oil rigs for predictive maintenance and safety monitoring.

Challenges in Adopting a Digital Thread

Here are the key challenges organizations may face when implementing a digital thread, along with potential solutions:

1. Data Silos

When information is locked within disconnected systems, collaboration suffers, and decision-making slows down. The solution is to invest in integration platforms and APIs to unify data flow.

2. High Implementation Costs

The significant upfront investment required can discourage small and medium-sized enterprises from adopting the digital thread. A phased implementation strategy helps spread costs over time and reduces financial strain.

3. Data Security Concerns

Important product information can be at risk of hacking. Using strong security measures like encryption and controlling who can access the data helps keep it safe.

4. Interoperability Issues

Different vendors’ systems often don’t work well together, causing problems. Using common rules and standards helps them share data smoothly.

5. Cultural Resistance

Employees and teams may resist new processes or technologies due to fear of change. Offering comprehensive training and strong change management programs helps foster acceptance and adoption.

Steps to Implement a Digital Thread

Here is a structured roadmap organizations can follow to adopt and optimize a digital thread successfully:

1. Assess Current Infrastructure

Evaluate existing systems, processes, and tools to identify integration gaps, data silos, and workflow inefficiencies before implementation begins.

2. Define Objectives

Establish clear, measurable goals that align the digital thread initiative with overall business strategies, operational efficiency targets, and customer needs.

3. Select the Right Tools

Choose appropriate PLM, ERP, IoT, and integration platforms to enable seamless data flow and connectivity between systems.

4. Standardize Data Formats

Implement consistent data structures, naming conventions, and formats to ensure interoperability, accuracy, and compatibility across diverse systems and platforms.

5. Integrate Systems

Connect various systems using tools like cloud, middleware, and APIs to provide automatic, secure, and fast data sharing.

6. Train Teams

Conduct targeted training programs so all stakeholders understand workflows, tools, and responsibilities in the new digital thread environment.

7. Monitor and Optimize

Continuously track performance metrics, analyze bottlenecks, and apply improvements to enhance efficiency, data quality, and decision-making capabilities.

Real World Examples

Here are some leading organizations successfully leveraging digital thread technologies to transform operations and product lifecycles:

1. Boeing

It uses a digital system to connect all aircraft data, helping predict when maintenance is needed, work more efficiently, and follow strict safety rules.

2. Siemens

Connects PLM and IoT platforms, integrating design, engineering, and manufacturing workflows for accelerated product development, delivery, and enhanced market responsiveness.

3. General Electric

Uses digital threads in turbine manufacturing, linking design blueprints with operational metrics to optimize performance, reliability, and maintenance strategies.

4. Lockheed Martin

Leverages digital thread to track every component across defense projects, ensuring traceability, regulatory compliance, and high-quality production standards.

Future Trends in Digital Thread

Here are the emerging developments that will shape the next generation of digital thread implementations:

1. AI-Driven Decision Making

2. Extended Reality Integration

3. Blockchain for Data Security

Blockchain keeps digital thread data safe with unchangeable records, making sure everyone involved can trust the information and follow the rules.

4. Industry-Specific Frameworks

Customized digital thread models will address sector-specific challenges in healthcare, construction, and retail, improving outcomes, compliance, and operational efficiencies significantly.

Final Thoughts

The Digital Thread revolutionizes product design, manufacturing, and servicing by linking all lifecycle stages for unmatched visibility, traceability, and efficiency. Despite challenges like costs and interoperability, its benefits—faster time-to-market, enhanced quality, and improved collaboration—are transformative. Blockchain, IoT, and AI advancements will enable companies of all sizes to operate more precisely, agilely, and customer-centrically.

Frequently Asked Questions (FAQs)

Q1. Is Digital Thread only for large enterprises?

Answer: No, while initially adopted by large enterprises, SMEs are increasingly adopting digital threads due to falling technology costs.

Q2. How is Digital Thread different from traditional PLM?

Answer: PLM focuses on product data management, while the digital thread connects all data sources across the product lifecycle for real-time insights.

Q3. Can Digital Thread work without IoT?

Answer: Yes, but IoT greatly enhances its value by providing real-time operational data.

Q4. How long does it take to implement a Digital Thread?

Answer: Implementation time varies from a few months to several years, depending on complexity and scope.

Recommended Articles

We hope that this EDUCBA information on “Digital Thread” was beneficial to you. You can view EDUCBA’s recommended articles for more information.