What is Just-in-Time (JIT)?

Just-in-Time (JIT) is a way of managing production and inventory where goods are made or obtained only when needed, in the right amount, and at the right place. By eliminating the need for large inventories, JIT minimizes waste, reduces storage costs, and frees up working capital.

Unlike traditional approaches that rely on forecast-based production, Just-in-Time emphasizes demand-pull systems, where real customer orders rather than predictions directly drive output. This creates an operational environment that is more responsive to customer needs and adaptable to fluctuations in demand.

Today, businesses apply JIT beyond manufacturing, using it in retail for real-time stock replenishment, in healthcare for on-demand delivery of surgical kits, in hospitality for fresh ingredient procurement, and software development through Agile and DevOps delivery pipelines.

Table of Contents

- What is Just-in-Time (JIT)?

- Origins and Historical Development

- Core Principles of Just-in-Time

- The Just-in-Time Process Flow

- Key Components and Tools of JIT

- Advantages of Just-in-Time

- Disadvantages and Risks of Just-in-Time

- Implementation Challenges

- JIT in Different Industries

- JIT vs. Traditional Inventory Management

- Modern Evolution of Just-in-Time

- Case Studies

Origins and Historical Development

JIT began in Japan after World War II, when industries had very limited raw materials, capital, and space. Toyota, under the leadership of Eiji Toyoda and the engineering genius Taiichi Ohno, sought to create a production system that would maximize efficiency and minimize waste.

Key historical milestones:

- 1950s – Early development: Inspired by the way American supermarkets restocked shelves based on consumption, Toyota developed a similar approach for its production lines.

- 1960s – Refinement: Toyota integrated JIT with jidoka (automation with human oversight) to form the Toyota Production System (TPS).

- 1970s – International recognition: The oil crisis highlighted the need for resource efficiency, attracting global interest in JIT.

- 1980s – Global expansion: American companies like Harley-Davidson and General Motors began adopting JIT principles to compete with Japanese efficiency.

- 1990s to Present: JIT evolved into a core component of Lean Manufacturing and spread beyond manufacturing to logistics, healthcare, and IT services.

Core Principles of Just-in-Time

The effectiveness of JIT relies on a few non-negotiable principles that form its backbone:

- Demand-driven production: Production starts only when there is actual demand. This avoids overproduction and ensures that goods do not sit idle in warehouses.

- Continuous flow: Products and materials move seamlessly through each stage of production without delays or unnecessary handling.

- Zero inventory philosophy: Inventory is kept at the minimum necessary to meet immediate needs, freeing up capital.

- Waste elimination (Muda): JIT targets the seven wastes identified by lean manufacturing: overproduction, waiting, transportation, overprocessing, excess inventory, unnecessary motion, and defects.

- Supplier integration: Strong, reliable supplier partnerships are essential to ensure timely and quality deliveries.

- Employee empowerment: Workers identify issues, halt production lines when necessary, and propose process improvements.

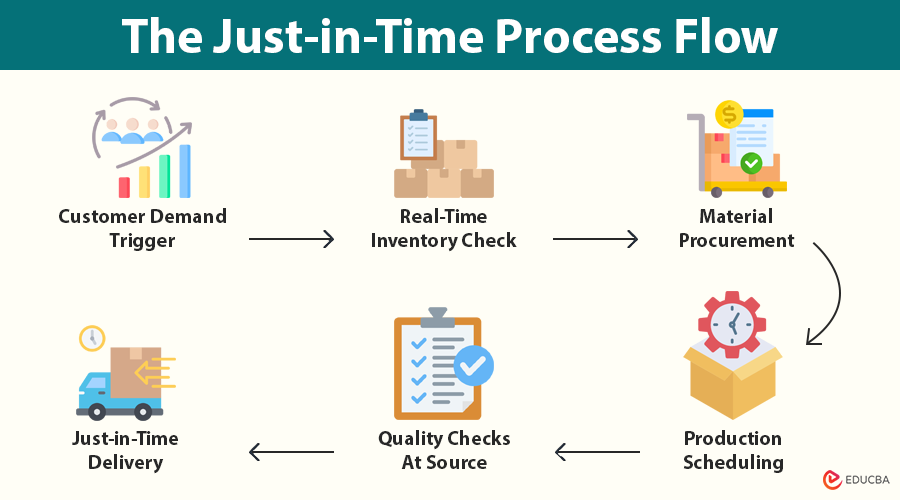

The Just-in-Time Process Flow

The Just-in-Time process follows a precise, feedback-driven cycle:

- Customer demand trigger: A sale, order, or consumption event signals the need for production or replenishment.

- Real-time inventory check: Inventory management systems confirm what is available and what needs replenishment.

- Material procurement: Small batches of materials are ordered from suppliers, timed to arrive just before production begins.

- Production scheduling: Production lines produce only what is needed, reducing changeover times and downtime.

- Quality checks at source: Each step includes quality verification to prevent defects from moving downstream.

- Just-in-time delivery: Finished goods are delivered immediately to the customer or the next stage in production.

This tight coordination ensures minimal waste, faster turnaround, and greater responsiveness to market changes.

Key Components and Tools of JIT

To function effectively, JIT relies on a set of tools and methods:

- Kanban system: A visual signaling method that uses cards, bins, or digital alerts to indicate when materials need replenishment.

- Takt time: The optimal production pace needed to meet customer demand without overproducing.

- SMED (Single-Minute Exchange of Die): Techniques to drastically reduce changeover times between production runs.

- Andon system: Visual displays that alert teams to problems in real-time, allowing for immediate action.

- Total Productive Maintenance (TPM): Preventive maintenance to avoid unplanned machine downtime.

- Heijunka (Production Leveling): Smoothing production to avoid peaks and troughs that strain the system.

Advantages of Just-in-Time

When implemented effectively, JIT offers several strategic advantages:

- Reduced inventory costs: Lower storage needs and less money tied up in stock.

- Faster cash flow: Payment for goods and materials happens closer to the time of sale.

- Higher quality output: Continuous quality checks prevent large-scale defects.

- Greater efficiency: Streamlined workflows reduce unnecessary steps.

- Better space utilization: Less inventory means more space for productive operations.

- Agility in the market: Ability to quickly adapt to shifts in customer preferences.

Disadvantages and Risks of Just-in-Time

Despite its benefits, JIT has inherent vulnerabilities:

- Supply chain disruptions: Natural disasters, strikes, or geopolitical events can halt production instantly.

- No safety net: With little or no safety stock, sudden demand surges can cause backorders.

- Supplier dependency: Reliance on a small number of reliable suppliers increases risk exposure.

- Implementation costs: Training, system upgrades, and supplier integration require significant upfront investment.

- Coordination complexity: Synchronizing multiple moving parts in real time can be challenging.

Implementation Challenges

Transitioning to Just-in-Time requires both structural and cultural changes:

- Cultural resistance: Employees accustomed to stockpiling inventory may resist the lean mindset.

- Supplier reliability: JIT demands suppliers with impeccable delivery performance and quality consistency.

- Technology investment: Real-time tracking systems, ERP platforms, and demand forecasting tools are necessary.

- Skill gaps: Train workers in problem-solving, lean techniques, and cross-functional tasks.

- Risk management: Companies must have contingency plans for disruptions, such as backup suppliers.

JIT in Different Industries

While manufacturing remains JIT’s core domain, its applications are vast:

- Automotive: Toyota, Honda, and BMW minimize parts storage by having suppliers deliver multiple times per day.

- Retail: Walmart uses POS data to trigger automatic replenishment of high-turnover products.

- Healthcare: Hospitals use JIT to ensure fresh blood supplies, avoiding waste from expired units.

- Food service: McDonald’s “Made for You” kitchen system cooks food only when ordered.

- Technology: Apple uses JIT in assembly plants to manage high-value components like processors and displays.

JIT vs. Traditional Inventory Management

| Aspect | Just-in-Time (JIT) | Traditional Inventory System |

| Inventory Levels | Minimal stock, replenished frequently | Large safety stock maintained |

| Trigger | Based on actual demand | Based on demand forecasts |

| Cost Efficiency | Lower holding and storage costs | Higher carrying costs |

| Flexibility | Highly adaptable to demand changes | Less responsive |

| Risk Exposure | High vulnerability to supply issues | Lower risk due to buffers |

Modern Evolution of Just-in-Time

Modern JIT has adapted to a more uncertain and interconnected global economy:

- Hybrid models: Combining JIT with Just-in-Case (JIC) inventory for critical items.

- Digital transformation: Using AI, IoT, and predictive analytics for real-time demand forecasting.

- Nearshoring: Locating suppliers closer to production facilities to reduce lead times.

- Sustainable JIT: Integrating environmental considerations, like reducing emissions from frequent shipments.

For example, Tesla uses a digitally enhanced JIT model, sourcing parts locally when possible and leveraging AI for supply chain visibility.

Case Studies

- Toyota: JIT is the foundation of its legendary efficiency. However, the 2011 earthquake highlighted its vulnerability to supply chain shocks.

- Dell: By building custom orders directly for customers, Dell avoided overproduction and reduced warehousing costs.

- McDonald’s: Uses JIT in food preparation, ensuring freshness and reducing waste by cooking items only when ordered.

- Zara: In fast fashion, Zara uses JIT to design, manufacture, and deliver new styles to stores within weeks, keeping inventory fresh.

Final Thoughts

Just-in-Time is more than an operational strategy; it is a mindset that values efficiency, waste elimination, and responsiveness. When implemented well, it can transform a company’s competitiveness. However, it demands discipline, trust, and resilience in the supply chain.

In a world where disruptions are becoming more frequent, the future of JIT lies in flexible hybrid systems, combining the cost advantages of lean inventory with the security of strategic buffers.

Frequently Asked Questions (FAQs)

Q1. How does JIT affect customer satisfaction?

Answer: JIT can improve customer satisfaction by ensuring fresher products, faster delivery, and more customization. However, supply disruptions can negatively impact order fulfillment.

Q2. What role does technology play in JIT?

Answer: Modern JIT depends heavily on technology such as ERP systems, inventory tracking software, IoT sensors, and AI-driven demand forecasting to ensure smooth coordination.

Q3. How is JIT different from Lean Manufacturing?

Answer: JIT is a specific inventory management and production strategy, while Lean Manufacturing is a broader philosophy focused on eliminating waste across all business processes. JIT is often one tool within a lean framework.

Q4. What skills do managers need to run a JIT system effectively?

Answer: Managers must excel in supply chain coordination, data analysis, contingency planning, and relationship building with suppliers.

Recommended Articles

We hope this guide on Just-in-Time (JIT) was helpful. Explore related articles on Lean Manufacturing, supply chain optimization, and inventory management strategies.