Helix Angle in CNC Milling: Overview

The helix angle in CNC milling may seem like a minor detail, yet it has a significant impact on the functionality of cutting tools. Knowing this angle might be the difference between a clean, effective cut and a stressful machining procedure for high or low helix. It is a basic geometric characteristic of cutting instruments such as helical end mills. This element may impact power needs, vibration, chip control, and other factors.

In this article, understanding the fundamentals of helix angle in CNC milling and how to calculate it will help you consistently achieve the best results, from determining the ideal helix angle to selecting the right tool for your job.

What is Helix Angle?

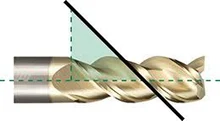

A helix is a smooth three-dimensional curve that spirals around a linear axis. The angle formed between a tool’s cutting edge and its axis is known as the “helix angle.” To put it simply, it is the steepness of the spiral flute on the end mill. This angle determines how the cutting tool interacts with the material and how effectively it removes chips during the milling process.

Helix Angle

A common helix angle in CNC milling is between 20° and 45 °. The right-angle helix would be a completely straight flute, which is 0°; however, the majority of end mills employ helix angles between 20° and 45°. This design provides maximum stiffness. Manufacturers use it in materials where chip evacuation is less important.

However, depending on the application, specialized machines may have considerably higher or lower angles. A lower helix angle (around 20°) delivers more strength to tougher material. In contrast, a higher helix angle (such as 45°) enables smoother cutting for softer materials and high-speed operations.

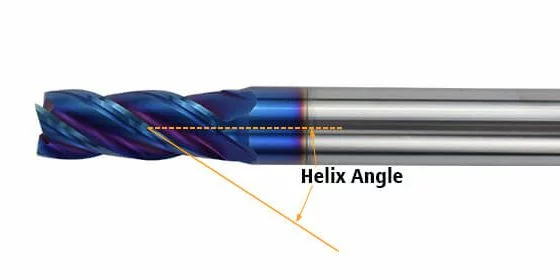

Helix Angle in Cutting Tool

Main Geometric Features of a Helix

Understanding the geometry is essential to maximizing the helix angle in CNC milling.

| Feature | Description |

| Central Axis | The fixed line around which the helix is formed serves as a reference for its location and orientation in 3D space. |

| Helix Angle | The angle between the coils of the helix and its central axis. High helix tools typically have angles of 35°–60°, which improves cutting efficiency and smoothness. |

| Pitch | The distance between two successive turns of the helix. In cutting tools, optimized pitch helps with effective chip evacuation and smoother machining. |

| Number of Turns/Flutes | The total number of spiral revolutions or flutes. High helix end mills usually have 2–4 flutes, balancing material removal and tool strength. |

| Sharp Cutting Edges | Cutting edges are designed to be sharp for smoother material engagement and precise cuts.. |

| Variable Helix Options

|

Some tools have slightly changing helix angles along the length to reduce vibration and chatter during high-speed machining |

| Coating Compatibility | High helix tools can be coated with TiN, TiAlN, or other protective layers to enhance wear resistance and tool life. |

| Durable Construction | Typically made from solid carbide for rigidity, heat resistance, and longer tool life. |

Helix Angle in CNC Milling

The measured tilt of the end mill with respect to its axis is known as the helix angle in CNC milling. This geometric characteristic has a direct impact on cutting dynamics, influencing the formation and evacuation of chips, the distribution of forces, and the final surface appearance. Finding the ideal helix angle is crucial for striking a balance between surface quality, tool strength, and productivity.

The Impact of Helix Angle on Cutting Efficiency

1. Evacuation of Chips

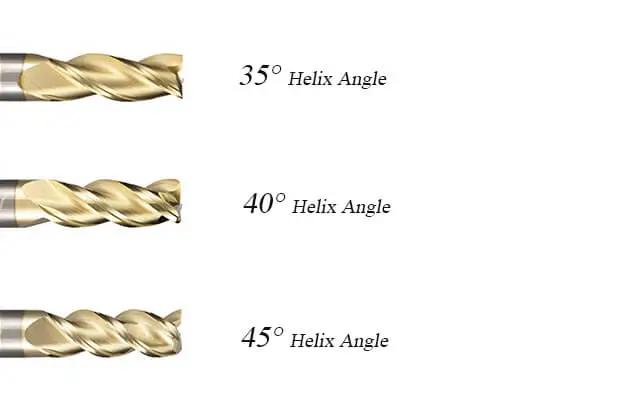

- A higher helix angle (e.g., 40° to 45°) is ideal for softer, slippery materials (such as copper and aluminum), resulting in a smoother cutting action that lifts chips rapidly and efficiently.

- In contrast, a lower helix angle (such as 20° to 30°) produces a stronger cutting edge when dealing with tougher materials.

Different Helix Angles

2. Cutting Power

- High helix reduces chatter and enhances surface smoothness by distributing cutting load more progressively along the edge.

- Low helix increases tool stiffness by directing more energy radially, but it can also cause vibration in parts with thin walls.

3. Finish of the Surface

- A high helix creates a smoother shearing motion, which improves the part’s surface polish.

- A low helix is better for roughing, but it is more susceptible to tool marks.

4. Tool Life

- High helix may wear more quickly due to its thinner core and slightly weaker cutting edge, although it lowers cutting forces in hard steels.

- Low helix has a stronger edge and longer tool life in abrasive materials.

Applications of Helix Angle in CNC Milling

| Helix Angle | Best For | Material Examples | Operation Type |

| 20°–30° (Low Helix) | Maximum edge strength, reduced deflection | Hardened steel, titanium, cast iron | Heavy roughing, interrupted cuts |

| 30° (Standard) | General-purpose balance | Mild steel, tool steel | Mixed roughing & finishing |

| 35°–45° (High Helix) | Smooth cutting, fast chip removal | Aluminum, stainless steel, plastics | Finishing, high-speed milling |

| Variable Helix | Vibration reduction, versatile | Mixed materials | High-speed finishing with chatter control |

Helix Angle Calculator

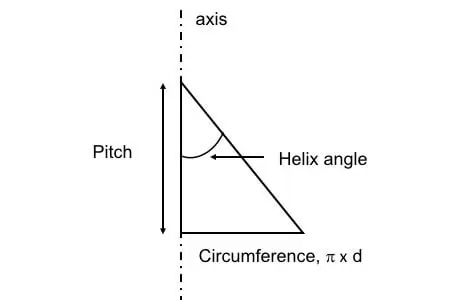

When using a helix angle calculator for screws, you can represent the section of the screw as a right triangle to calculate the angle. This term directly refers to screws, hence it is mostly used in the majority of mechanical applications involving helix angles.

By unwinding a single round of the helix, we can represent the circumference of a circle with diameter d. The angle formed by this circumference and the helix’s pitch is known as the helix angle.

Helix Angle Formula

You can compute this analytically as follows:

Helix angle = Atan (Lead of Screw/Circumference of Screw) or α= atan(L/C) is employed to compute the Helix Angle, denoted by the symbol α.

Note: The inverse of the Tan function, the Atan or arc tangent function, is used to determine the value (in radians) of the angle whose tangent equals a given integer.

- L the Lead of Screw: how far the nut travels during a single screw turn.

- Measure the diameter of the screw, then multiply the result by pi to calculate the radius of the screw thread or gear, which establishes the circumference of the screw.

The angle created between the tool’s centerline and a line tangent to the cutting edge is the cutting tool’s helix angle. These forces impact cutting pressures, material removal rate, chip evacuation, and surface polish.

Generally, the cutting edge wraps around the tool more quickly when the helix angle exceeds 40°. At an angle less than 40°, the cutting edge wraps more slowly.

The length of interaction along the cutting edge will also shorten as the helix angle rises. Therefore, while machining a component, it is necessary to weigh the advantages and disadvantages of employing both slow and high helix angles.

Benefits and Drawbacks of Low vs High Helix End Mills

Generally, the cutting edge wraps around the tool more quickly when the helix angle exceeds 40°. An angle less than 40° produces a slower wrap. The table below represents low vs high helix end mills:

Helix Angle Tools

| Helix Angle | Features | Benefits of Low vs High Helix End Mill | Drawbacks of Low vs High Helix End Mill |

| Low Helix (<40°) | Slower wrap of cutting edge; longer engagement along cutting edge | Reduced Lifting: The slower helix minimizes the risk of the workpiece lifting off the table in less stable setups.

Larger Chip Removal: Stronger edge geometry allows more aggressive machining, though chip evacuation is less efficient.

Increased Strength: A robust core helps the tool withstand pressure and resist deformation. |

Slower Feed Rate: Requires slower operation due to higher cutting forces.

Rougher Finish: Less effective chip evacuation can result in a lower-quality surface finish. |

| High Helix (>40°)/ High Helix End Mill | Steep flute geometry; faster cutting-edge wrap; shorter engagement length | Better Surface Finish: Lower radial forces and a steeper helix improve shearing action, yielding smoother surfaces.

Effective Chip Evacuation: Shorter cutting-edge engagement helps remove chips efficiently.

Lower Radial Force: Quieter, smoother operation with reduced deflection and enhanced stability, especially for thin walls. |

Thinner Teeth: High helix tools have thinner flutes, which are less robust.

Higher Risk of Deflection: Increased likelihood of tool deflection limits cutting speed.

Potential Poor Finish or Tool Failure: Excessive deflection can harm surface quality or even cause tool breakage. |

Choosing the Right Helix Angle in CNC Milling

When selecting the helix angle in CNC milling, consider:

1) Fulfilling Needs for Productivity

A lower helix angle is ideal for achieving quick material removal. You can mitigate the disadvantages by using compensatory techniques, such as employing low-helix tools for rough cuts and high-helix tools for finishing.

2) Pocketing Effectively

Efficient chip handling is essential in pocketing operations. Choosing a high helix angle improves chip evacuation and shields tools and part quality from harm.

3) Handling Thin Floors and Walls

Cutting forces have the potential to distort thin walls and floors. The helix angle directly influences these forces. Therefore, to achieve precise finishes and minimize radial stresses, use a tool with a high helix angle.

4) Tool Life Balance

A high helix cutting edge shortens tool life by weakening the cutter core. Low helix also affects tool performance by causing issues such as heat buildup and inadequate chip evacuation. You must carefully consider the helix angle to achieve optimal tool life.

Final Thoughts

The helix angle in CNC milling may seem like a minor geometric detail, but it plays a crucial role in achieving machining success. From chip evacuation to surface finish and tool life, choosing the correct helix angle ensures higher efficiency, better quality, and longer tool durability. By matching the helix angle with the material and operation type, you can consistently achieve superior results in CNC milling projects.

Recommended Articles

We hope this comprehensive guide to the helix angle in CNC milling was helpful. Explore related articles on CNC machining, cutting tools, and manufacturing techniques to deepen your knowledge and boost your machining efficiency.