What is Fiber Splicing?

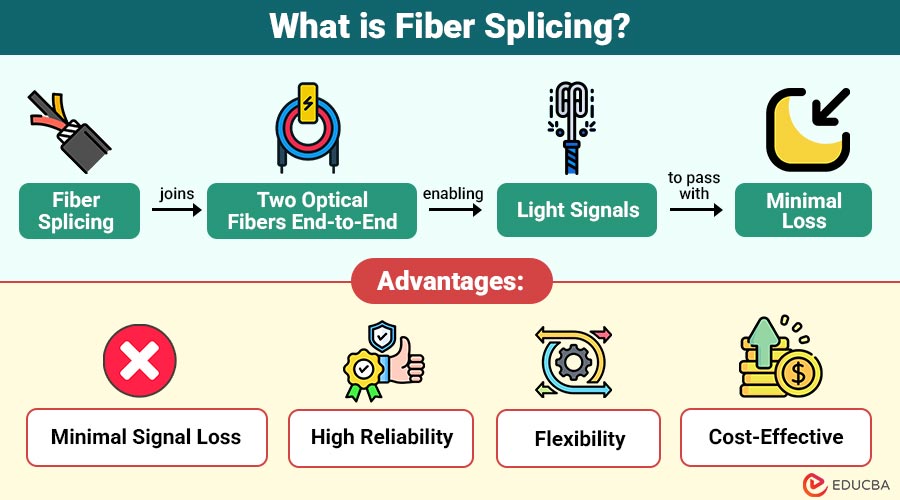

Fiber splicing is the method of joining two optical fibers end-to-end to enable light signals to pass with minimal loss. Unlike connectors, which allow fibers to be plugged and unplugged, splicing provides a permanent or semi-permanent connection

Splicing is essential when:

- Extending the length of a fiber cable.

- Repairing a damaged fiber line.

- Connecting fibers during network installations.

- Creating a joint in long-haul communication lines.

Table of Contents:

- Meaning

- Importance

- Methods

- When is Fiber Splicing Needed?

- Advantages

- Disadvantages

- Real World Applications

Key Takeaways:

- Fiber splicing provides permanent optical fiber connections, ensuring smooth, reliable communication with minimal data loss.

- Fusion splicing delivers durable, low-loss joints, while mechanical splicing offers faster, cost-effective temporary connections.

- Industries like telecom, medicine, and defense depend on fiber splicing for efficient, secure, and high-speed communication.

- Although costly and skill-dependent, fiber splicing remains essential for building scalable, future-ready digital infrastructure worldwide.

Why Fiber Splicing is Important?

It is important because it ensures:

1. Signal Continuity

Keeps data transmission smooth by connecting fibers seamlessly, avoiding breaks or interruptions, ensuring continuous, stable network communication flow.

2. Low Signal Loss

It minimizes light loss at fiber joints, allowing efficient long-distance communication with strong, clear signals, critical for telecom and internet services.

3. Durability

Fusion-spliced fibers form strong, permanent joints that withstand environmental stress, providing reliable, long-term connectivity without frequent repairs or maintenance interruptions.

4. Cost Savings

Splicing reduces reliance on costly fiber connectors, lowering installation expenses and overall network maintenance costs, making it a highly economical solution.

Methods of Fiber Splicing

It is done in two main ways:

1. Fusion Splicing

Fusion splicing involves permanently joining two optical fibers by heating and fusing them using an electric arc.

Steps in Fusion Splicing:

- Strip the protective coating from both fiber ends.

- Clean and cleave the fiber ends for a smooth surface.

- Align the fibers in a fusion splicer.

- Use an electric arc to fuse the fiber ends.

- Protect the splice with a heat-shrink sleeve.

Advantages:

- Very low insertion loss (0.02 dB typical).

- High strength and durability.

- Permanent solution.

Disadvantages:

- Requires expensive fusion splicing equipment.

- Needs skilled technicians.

- Time-Consuming Process

2. Mechanical Splicing

Mechanical splicing aligns two fiber ends inside a mechanical fixture, often using index-matching gel to minimize loss.

Steps in Mechanical Splicing:

- Strip and clean fiber ends.

- Cleave the fibers with precision.

- Insert into a mechanical splice holder with alignment grooves.

- Apply gel or adhesive for light transmission.

Advantages:

- Less expensive equipment than fusion splicing.

- Quick and simple process.

- Ideal for temporary or emergency repairs.

Disadvantages:

- Higher insertion loss (0.2 – 0.75 dB typical).

- Less durable compared to fusion splicing.

- Susceptible to environmental factors.

When is Fiber Splicing Needed?

Here are the key scenarios where it becomes essential:

1. Fiber Cable Installation

Required during new installations to join multiple cable segments securely, ensuring continuous connectivity and smooth signal transmission across the entire network infrastructure.

2. Network Expansion

When expanding an existing fiber optic network, splicing connects new fibers with current lines, allowing seamless extension of services while maintaining strong performance and uninterrupted communication flow.

3. Cable Repair

In cases of accidental cuts or damages caused by construction, splicing restores the fiber link by reconnecting broken ends, quickly re-establishing network performance and data transmission.

4. Undersea Fiber Cables

During submarine cable deployment, splicing connects long fiber segments underwater, enabling global internet connectivity across continents while ensuring durability, reliability, and minimal signal loss in challenging environments.

Advantages of Fiber Splicing

It offers several advantages that enhance network performance and reliability:

1. Minimal Signal Loss

Fusion splicing keeps signal strong and clear with very little loss, which is important for fast, long-distance communication networks.

2. High Reliability

Spliced fiber joints are durable and resistant to environmental stress, offering reliable, long-term performance without frequent failures or disruptions in connectivity.

3. Flexibility

Splicing allows seamless integration of new cables into existing networks, enabling upgrades, expansions, and modifications without replacing the entire fiber infrastructure.

4. Cost-Effective

By reducing the reliance on costly connectors, splicing lowers installation and maintenance expenses, making large-scale fiber optic networks more affordable overall.

Disadvantages of Fiber Splicing

While it offers many benefits, it also comes with certain disadvantages:

1. Equipment Cost

Fusion splicing machines are highly expensive, making initial investment costly for organizations, especially smaller firms or startups deploying fiber networks.

2. Skilled Labor Required

Splicing demands precision, steady hands, and expertise. Without trained technicians, errors may occur, increasing signal loss and reducing network reliability.

3. Time-Consuming

Fusion splicing involves multiple steps, including preparation, alignment, and fusion, making the process slower compared to simple connector-based alternatives.

4. Maintenance Complexity

Mechanical splices often weaken or degrade over time due to environmental factors, requiring periodic inspections, repairs, or replacements for optimal performance.

Real World Applications of Fiber Splicing

1. Telecommunications

It enables the construction of robust backbone telecom networks, delivering high-speed internet, reliable voice communication, and uninterrupted mobile services globally.

2. Submarine Cable Systems

Undersea fiber cables connecting continents rely on fusion splicing, ensuring long-distance, secure, low-loss signal transmission essential for global internet connectivity.

3. Enterprise Networks

Large organizations utilize fiber splicing to interconnect multiple office buildings seamlessly, supporting high-speed data transfer, cloud services, and efficient enterprise communication systems.

4. Medical Industry

5. Defense and Aerospace

Military and aerospace networks use splicing for secure, durable fiber connections, supporting encrypted communication, navigation systems, and mission-critical defense operations worldwide.

Final Thoughts

Fiber splicing is a vital process in building and maintaining modern communication networks. Whether it is creating long-haul submarine cables, repairing damaged fibers, or expanding enterprise networks, splicing ensures seamless, reliable, and high-speed data transmission. Fusion splicing stands out as the preferred method for permanent, low-loss, and durable connections, while mechanical splicing offers a practical solution for temporary or emergency connections. With the growing demand for fiber optic connectivity in 5G, cloud computing, and IoT applications, splicing will continue to play a central role in shaping the digital future.

Frequently Asked Questions (FAQs)

Q1. Which splicing method is better – fusion or mechanical?

Answer: Fusion splicing is better for permanent, high-quality connections due to its low loss and high strength. Mechanical splicing is more suitable for temporary or quick fixes.

Q2. How much does fiber splicing cost?

Answer: Fusion splicers can cost several thousand dollars, but the cost per splice is very low. Mechanical splice kits are cheaper but incur higher per-joint losses.

Q3. Can anyone perform fiber splicing?

Answer: While basic mechanical splicing can be done with minimal training, fusion splicing requires skilled technicians to ensure precision and minimal signal loss.

Q4. How long does a splice last?

Answer: Fusion splices can last for decades if protected properly, whereas mechanical splices may degrade faster due to environmental conditions.

Recommended Articles

We hope that this EDUCBA information on “Fiber Splicing” was beneficial to you. You can view EDUCBA’s recommended articles for more information.