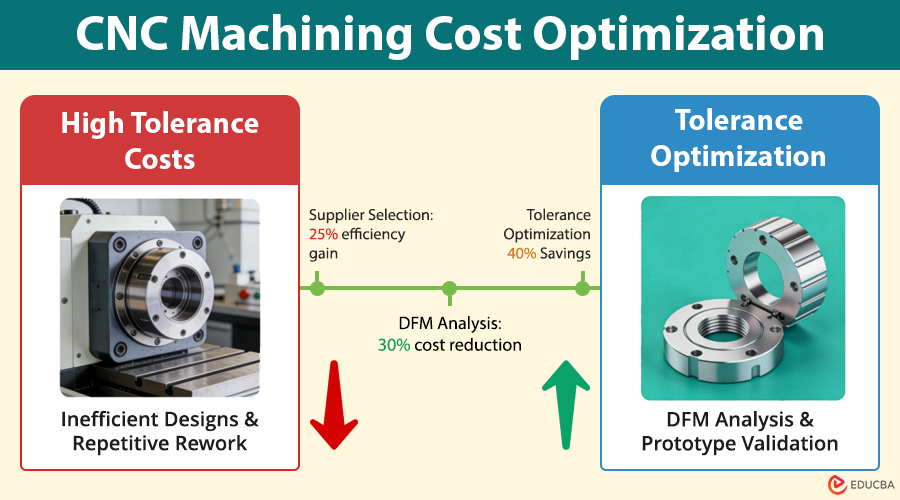

Figure 1: Implementing key strategies like tolerance optimization and DFM analysis can reduce CNC machining costs by up to 40% while maintaining quality standards.

The Importance of CNC Machining Cost Optimization

Modern manufacturing is brutally competitive, and cost control is paramount. Unfortunately, when selecting CNC machining services, way too many companies compare only material prices and hourly rates. At the same time, some very important levers remain buried beneath the surface, unseen. This article reveals five widely overlooked methods to optimize CNC machining costs and help you plan your next project efficiently.

5 Key Strategies for CNC Machining Cost Optimization

Here are 5 key strategies for CNC machining cost optimization:

1. Hidden Cost Drivers

While cost analysis generally begins with material selection, true CNC machining cost optimization extends further to fixturing complexity, machine setup time, and CAM programming efficiency. A part requiring a complex custom fixture will have higher upfront costs than one designed for standard workholding. Efficient toolpath programming directly reduces machining time. The first step toward cost optimization is partnering with a CNC manufacturer that has advanced software and deep experience.

2. Optimizing Tolerances

Tolerances are the base of precision, but not every feature needs ultra-tight accuracy. Overdimensioned parts with unnecessarily tight tolerances drive costs up exponentially through slower feeds, frequent quality checks, and increased scrap. Engineers analyze critical functions to determine which tolerances are essential and which they can loosen. For instance, a non-critical mounting hole may only need ±0.1mm instead of ±0.025mm. This single CNC machining cost optimization tactic can reduce part costs by up to 40% without affecting performance, especially when suppliers follow ISO 9001:2015 and IATF 16949 standards.

3. Designing for CNC

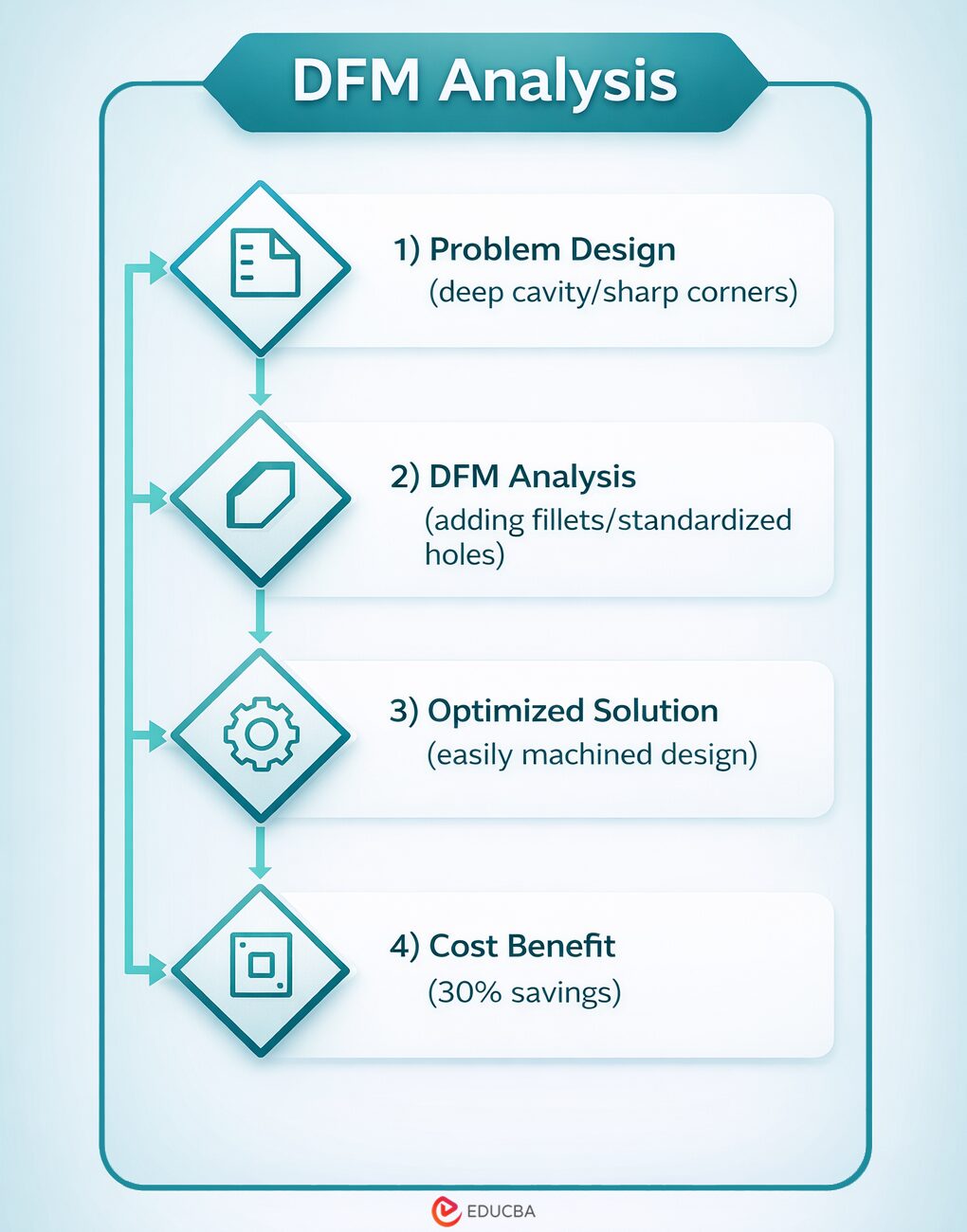

Even a perfect CAD model can still cause machining challenges, unnecessarily driving up costs. Deep pockets require long-reach tools, and internal sharp corners often need expensive EDM operations. Design for Manufacturing (DFM) analysis helps optimize designs prior to production by adding fillets, avoiding deep cavities, and standardizing hole sizes. Manufacturers often provide free DFM feedback during the quoting process. Integrating CNC machining cost optimization into the design stage improves both efficiency and part quality. For gears, DFM should also consider tooth profile accuracy and heat treatment distortions.

Figure 2: DFM analysis finds design flaws early in the process when modifications are inexpensive, avoiding costly manufacturing changes.

4. Prototyping

Effective CNC machining cost optimization begins at the prototyping stage. During design validation, for example, rapid prototyping technologies such as 3D Printing or quick-turn CNC prototypes enable you to perform low-cost checks on design, fit, and function. Rectifying defects during this stage costs far less than fixing them after customers discover them in mass production. A nylon prototype created via SLS 3D printing can effectively simulate an injection-moulded part, for instance. When validated, going to high-volume plastic injection moulding will help avoid costly mould modifications.

5. Surface Finishing

Surface finishes impact aesthetics, corrosion resistance, and wear, but choices can dramatically affect cost. Internal components may only require bead blasting rather than hard anodizing, and optimized CNC parameters can produce superior as-machined finishes, reducing post-processing. Collaborating with your manufacturer to select the most economical finish is another key lever for optimizing CNC machining costs.

Key Factors When Choosing a Manufacturing Partner

The lowest quote often does not equal the lowest total cost. For effective CNC machining cost optimization, look for:

- Comprehensive capability: CNC machining, sheet metal fabrication, injection molding, etc. Recommending the most appropriate technology for your project.

- Comprehensive quality assurance system: ISO 13485 (medical), AS9100D (aerospace) certified. The manufacturing company ensures product consistency and reliability, eliminating the “hidden” costs of rework and time delays.

- Transparency in communication & project management: From instant quoting to production tracking, transparency means clear expectations of cost and timeline.

- Engineering support: Expert advice on DFM and cost optimization saves customers money at the source. Expert guidance on DFM and CNC machining cost optimization reduces unnecessary costs at the source.

Final Thoughts

CNC machining cost optimization is a structured process that goes far beyond price comparisons. By focusing on tolerance strategies, DFM, prototyping, surface finishing, and choosing a capable manufacturing partner, businesses can achieve substantial cost savings, improved product quality, and faster time-to-market.

Frequently Asked Questions (FAQs)

Q1. What is the biggest cost driver in CNC machining?

Answer: Besides material and machine time, the main factors are part geometry complexity, tolerance requirements, surface finish specifications, and order quantity. Complex designs require longer programming and machining times.

Q2. Is CNC machining suited for low-volume productions?

Answer: Yes, it is ideal. CNC machining requires no tooling, offering great flexibility for low-volume production and rapid prototyping. For very high volumes, injection molding could be more economical.

Q3. How can I ensure that my CNC-machined parts are of high quality?

Answer: You must select any supplier based on their sound quality control system. It must include FAI, in-process checks, and final inspection with equipment such as CMMs.

Q4. Which is cheaper to machine: aluminum or steel?

Answer: Generally, it is easier to machine aluminum than steel. Therefore, tool wear is less and cycle times are faster; thus, it is cheaper. The final choice depends on the part’s strength, weight, and application requirements.

Q5. How do we ensure a seamless transition from a prototype to mass production?

Answer: This is where one selects a manufacturer that can provide full-service capabilities, ranging from 3D printing and CNC prototyping to injection molding. This way, design data remains consistent, and learnings from prototyping can have a direct impact on mass production.

Author Bio:

The knowledge in this article comes from the manufacturing experts at LS Manufacturing, helping engineers and businesses solve complex component challenges with precision CNC machining services. For personalized solutions and CNC machining cost optimization strategies, visit their website for real-world advice and step-by-step guidance.

Recommended Articles

Explore these recommended articles to discover practical strategies for CNC machining cost optimization, design for manufacturability, and prototyping efficiency. Gain expert insights to reduce manufacturing costs, improve part quality, and streamline production workflows.