Introduction to Sugar Syrup Filtration

Filtration is often an unsung hero in modern industrial processes, quietly ensuring the purity, safety, and quality of countless products we consume daily. Among them, sugar syrup filtration stands out, as its clarity and consistency are essential for wide-ranging applications from sweeteners in food production to raw materials in industrial manufacturing. This article explains how Yuwei Filter systems improve sugar syrup production, the main filtration steps involved, and why these advances matter for both producers and consumers.

Why Filtration is Key to Sugar Syrup Production?

Sugar syrup is an important part of sweets, drinks, medicines, and more. But making good sugar syrup takes more than just mixing sugar and water. The raw materials, often derived from sugarcane or sugar beets, contain impurities like fibers, soil particles, and dissolved salts. Left unfiltered, these impurities can affect the syrup’s viscosity, taste, transparency, and shelf life.

This is where sugar syrup filtration systems come into play. By removing unwanted contaminants and particles, filtration ensures that sugar syrup meets the rigorous standards required by food and industrial applications while maintaining its appealing visual clarity and consistency.

Source: yw-wellfilter

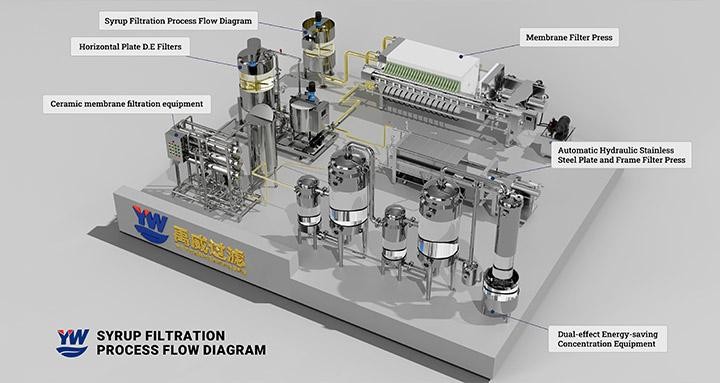

The Sugar Syrup Filtration Process

The sugar syrup filtration involves several steps designed to refine the raw mixture into a clear, pure product. Below, we break down the key stages of the process:

1. Pre-Filtration or Clarification

Raw sugar syrup first goes through a clarification stage that removes larger impurities like plant fibers, residual sand, and unprocessed solids. This is where equipment like Chamber Filter Presses excels. These presses use a robust chamber system to retain larger particles while allowing the purified liquid to pass through. The advantage of this method is its ability to handle bulk volumes efficiently. Chamber Filter Presses serve as a workhorse in sugar production, effectively preparing the syrup for finer filtration stages.

2. Fine Filtration

Following the initial clarification, the sugar syrup undergoes fine filtration. This step targets microscopic impurities, including undissolved sugar crystals and microfibers. Here, Plate and Frame Filter Presses are commonly used. These systems employ alternating plates and frames equipped with filter cloths or membranes to achieve precise filtration levels. The design flexibility of Plate and Frame Filter Presses allows manufacturers to adjust filtration precision depending on the desired syrup quality, making them invaluable for ensuring consistency across batches.

3. Membrane Filtration

For ultra-fine filtration, Membrane Filter Presses take center stage. This advanced system uses semi-permeable membranes that can capture impurities at a molecular level. Membrane filters are particularly effective for removing proteins, colloidal particles, and fine precipitates that standard filter presses might miss. One of the key benefits of membrane presses is their use of controlled pressure. This allows for better moisture removal and higher filtration accuracy, resulting in a more concentrated and higher-quality syrup product.

4. Polishing Filter Stage

A polishing filter stage often achieves a crystal-clear finish on the sugar syrup. Options like the Stainless Steel Filter Press are ideal here due to their durability and resistance to corrosion. These systems not only deliver exceptional filtration results but also maintain an impeccable sanitary standard – an essential requirement in food-grade processes.

5. Mobile Filtration Systems

Increasingly, manufacturers are also leveraging Mobile Filter Presses for flexible production needs. These portable systems allow producers to adapt filtration processes to different production sites or varying batch volumes, maintaining efficiency while reducing downtime.

The Benefits of Advanced Filtration in Sugar Syrup Production

The following benefits highlight how advanced sugar syrup filtration systems improve production quality, efficiency, and sustainability.

1. Enhanced Product Quality

Filtration directly impacts the clarity, taste, and consistency of sugar syrup. High-quality filtration equipment ensures that each syrup batch meets stringent standards, which is critical for customer satisfaction and brand reputation.

2. Improved Efficiency

Modern filtration systems, like Membrane and Chamber Filter Presses, are designed to handle large volumes with minimal energy consumption. This efficiency saves operating costs and ensures a seamless production workflow for manufacturers.

3. Compliance with Industry Standards

The food industry is tightly regulated, requiring strict adherence to hygiene and quality standards. Stainless Steel and Mobile Filter Presses meet these demands by offering sanitary, flexible, and highly effective filtration solutions, helping producers stay compliant while reducing risks.

4. Resource Savings

Advanced filtration systems also contribute to sustainable production by reducing waste, minimizing water usage, and reclaiming dissolved sugar from processing byproducts. These innovations help manufacturers optimize resource use and reduce their environmental impact.

5. Scalability

State-of-the-art filtration equipment is designed with scalability in mind, allowing businesses to scale their operations efficiently without compromising on quality. Whether producing small experimental batches for product development or large commercial volumes, equipment like Membrane Filter Presses adapts to these varying demands.

Technological Innovations in Sugar Syrup Filtration

The filtration industry has continuously evolved to meet the demands of modern sugar syrup production. Some notable advancements include:

- Automated Filter Press Systems: Automation reduces human intervention, enabling continuous production with minimal downtime. Automated systems also improve precision and consistency across filtration cycles.

- Enhanced Filtration Media: New developments in filter cloths and membranes allow for greater filtration accuracy. These materials can now capture micron-sized particles while remaining resistant to clogging.

- Eco-Friendly Designs: Manufacturers are increasingly prioritizing sustainability, incorporating energy-efficient components and recyclable materials into filtration systems. This ensures a lower environmental footprint without compromising results.

The Future of Sugar Syrup Filtration

Rising consumer demand for higher-quality and sustainably produced food products is driving further innovation in the filtration industry. Expect to see improved membrane technologies, AI-assisted filtration systems for real-time monitoring, and further enhancements in mobile filtration solutions. These advancements will make sugar syrup production more efficient, sustainable, and adaptable to global market demands. Filtration plays a pivotal role in transforming raw sugar syrup into a pure, high-quality ingredient that forms the backbone of countless products we use every day.

From initial clarification to ultra-fine filtration stages, advanced filtration systems like Chamber Filter Presses, Plate and Frame Presses, and Membrane Presses have redefined the production process, setting new standards for efficiency, quality, and sustainability. Whether you are a manufacturer seeking to improve operational efficiency or an industry enthusiast curious about technological progress, the evolution of filtration systems in sugar syrup production illustrates how innovations in this field continue to enhance our lives behind the scenes.

Final Thoughts

Sugar syrup filtration is essential for turning raw syrup into a pure, high-quality ingredient used in many products. Advanced filtration methods like Chamber Filter Presses, Plate and Frame Presses, and Membrane Presses have improved quality, efficiency, and sustainability in sugar syrup production. Whether you are a manufacturer aiming to improve your process or someone interested in industrial technology, understanding sugar syrup filtration shows how this critical step impacts the food and beverage industry behind the scenes.

Recommended Articles

We hope this guide on sugar syrup filtration helps you achieve better quality and consistency in your production process. Check out these recommended articles for more such topics.