Introduction to Retail Display Execution

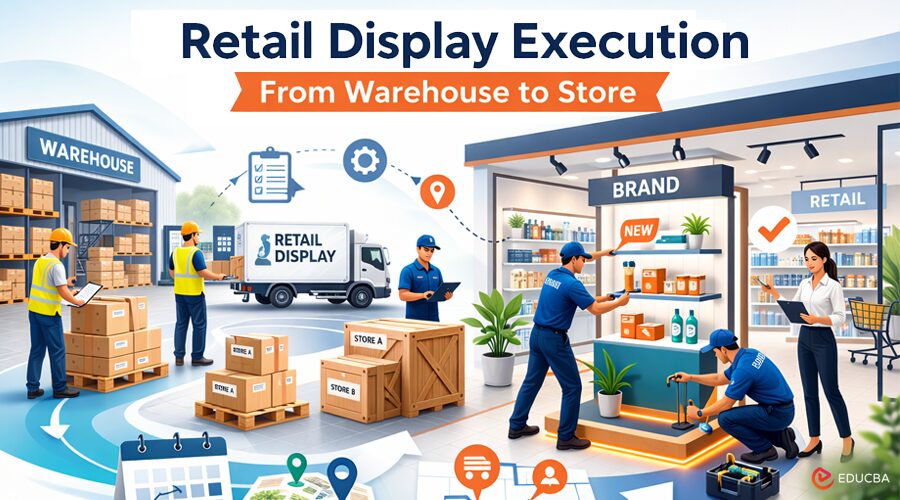

Retail displays play a quiet but powerful role in how people shop. They guide attention, shape first impressions, and often decide whether a customer stops or walks past. However, a retail display does not begin on the store floor. The process begins much earlier, as teams pack the display in crates in the warehouse and prepare it for proper handling, movement, and installation.

The journey from warehouse to store is where success or failure often happens. This is where retail display installation matters most. A display can look perfect in a design file but still fail if it is not installed correctly in real store conditions.

This article explains how retail displays move from storage to store floors and what it takes to ensure strong Retail Display Execution once they are live.

Why Retail Display Execution Matters as Much as Design?

Many people think retail displays are all about design. Color, shape, lighting, and layout are important, but Retail Display Execution brings design to life.

Poor execution can lead to:

- Displays that look uneven or unstable

- Missing parts or damaged fixtures

- Delays that cause missed launches

- Safety issues for staff and customers

- Inconsistent setups across locations.

Strong installation ensures the display looks as planned and performs as intended in real-world store conditions.

Retail Display Execution Process

Step 1: Preparing Displays in the Warehouse

Before a display ever reaches a store, preparation starts in the warehouse. Many teams overlook this step, but it sets the tone for successful Retail Display Execution.

Key preparation steps include:

- Checking that all parts are complete

- Labeling components clearly

- Packing displays in a way that protects them during transport

- Organizing materials by store or region.

When warehouse teams properly prepare displays, Retail Display Execution teams spend less time resolving issues on-site. This saves time, reduces errors, and keeps projects on schedule.

Step 2: Coordinating Logistics and Delivery

Retail environments are busy places. Deliveries must happen at the right time, often outside normal store hours. Displays need to arrive when stores are ready to receive them.

Effective logistics planning for installation includes:

- Scheduling deliveries around store operations

- Coordinating with store managers

- Planning routes for multi-location rollouts

- Making sure the equipment arrives with the displays.

Even the most skilled installers cannot execute properly if materials arrive late or incomplete. Logistics is a critical part of Retail Display Execution success.

Step 3: Understanding the Store Environment

No two stores are the same. Floor space, ceiling height, lighting, and customer flow can all differ.

Before installation begins, Retail Display Execution teams need to:

- Review store layouts

- Identify obstacles like columns or low ceilings

- Understand safety rules and local requirements

- Adjust plans without changing brand intent.

This is where experience matters. Skilled teams know how to adapt Retail Display Execution to real-store conditions without compromising the brand’s message.

Step 4: Installation on the Store Floor

This is the most visible part of the process. It is also the moment when everything must come together smoothly.

Professional Retail Display Execution focuses on:

- Accurate placement

- Secure assembly

- Clean finishes

- Safety for staff and shoppers

- Minimal disruption to store operations.

Installers often work early mornings, late nights, or overnight. The goal is simple. When customers walk in, the display should already look complete and natural, as if it has always been there.

Consistency Across Multiple Locations

Many retail brands launch the same display across dozens or hundreds of stores. Consistency is critical. A display that looks great in one store but sloppy in another weakens the brand message.

Consistent installation depends on:

- Clear installation guidelines

- Trained installation teams

- Quality checks during and after setup

- Strong communication across regions.

Retail Display Execution at scale requires structure. Without it, small mistakes multiply across locations.

Safety Is Not Optional

Retail displays must be safe. This is not just about following rules. It is about protecting people.

Safe installation includes:

- Securing fixtures properly

- Managing electrical components carefully

- Ensuring displays do not block exits or aisles

- Using materials that meet store standards.

A display that looks good but creates risk is not successful. Safety is part of performance and an essential element of Retail Display Execution.

Measuring Whether a Display Performs

After installation, the team must continue monitoring performance. Performance matters.

Signs of strong installation include:

- Strong visibility

- Clear product access

- Minimal damage over time

- Positive feedback from store staff

- Fewer maintenance issues.

While sales results depend on many factors, proper Retail Display Execution supports better outcomes by allowing the display to do its job without distractions or flaws.

Common Mistakes That Reduce Impact

Many retail displays fail not because of bad ideas, but because of avoidable mistakes.

Common issues include:

- Rushing installation

- Ignoring store-specific conditions

- Poor communication between teams

- Inconsistent execution across locations

- Lack of post-installation checks.

These problems often cost more to fix later than to prevent upfront.

Why Professional Retail Display Execution Makes a Difference?

Retail Display Execution is not just assembly. It is coordination, planning, and structured implementation working together.

Experienced Retail Display installation teams understand:

- Retail schedules

- Store operations

- Brand standards

- Safety requirements

- Real-world challenges.

This experience helps display moving smoothly from warehouse to wow factor without unnecessary stress.

A Practical Approach to Retail Display Execution

The best retail display projects focus on clarity and discipline. They do not overpromise. They focus on doing the basics well every time.

That includes:

- Clear planning

- Organized logistics

- Skilled installation

- Consistent quality

- Respect for the store environment.

This approach supports displays that look good, last longer, and effectively convey the brand message.

Final Thoughts

Retail displays succeed when design and execution work together. The journey from warehouse to store floor is where many displays either come to life or fall apart.

Retail Display installation plays a central role in this journey. It connects planning with reality and turns ideas into something customers can see and trust.

For brands looking to manage this process with care and professionalism, working with experienced partners like Teamwork can help ensure displays are installed correctly and consistently, with respect for real retail environments.

Recommended Articles

We hope this guide on Retail Display Execution helps you plan, coordinate, and implement high-performing in-store displays with confidence. Explore these recommended articles for deeper insights, practical frameworks, and expert strategies to optimize retail rollouts and installation success.