Introduction to Restaurant Logistics Solutions

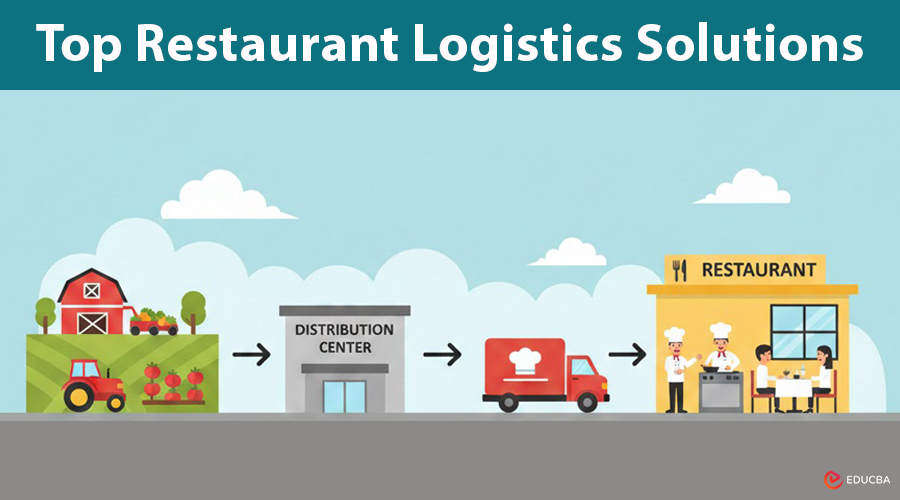

The food service industry has changed. What started as a business built around four walls and dining rooms has expanded into meal kits, eCommerce, retail shelves, and multi-location franchise operations. For restaurant owners, commissary kitchen operators, and QSR brands, this growth creates logistical challenges that in-house teams were never designed to handle.

Traditional restaurant operations focus on prep, service, and hospitality. They do not include managing inventory for an online store, coordinating wholesale shipments to grocery chains, or ensuring that franchise locations receive branded packaging on time. When brands try to handle these tasks internally, the result is often wasted labor, missed deadlines, and operational bottlenecks that slow growth rather than support it.

Restaurant logistics solutions are built specifically to address these challenges. They support temperature control, regulatory compliance, multi-channel distribution, and seasonal demand without pulling internal teams away from core operations. Below are five restaurant logistics solutions that help restaurants, commissary kitchens, and specialty food brands scale efficiently while maintaining quality and consistency.

Top 5 Restaurant Logistics Solutions

Here are some restaurant logistics solutions that help food businesses streamline distribution, maintain quality, and scale efficiently across multiple sales channels.

1. Specialized Food and Beverage Storage

Storage needs for food businesses go far beyond racking and square footage. Products have shelf lives. Some require climate control. Others need to be tracked by batch or lot number for compliance and recall management. General warehousing providers do not always have the infrastructure or expertise to meet these requirements, putting brands at risk.

Specialized restaurant logistics solutions include food-grade storage facilities with temperature-controlled environments, allergen segregation, and real-time inventory tracking. These capabilities protect product integrity and provide the traceability retailers and distributors demand.

- Temperature-controlled zones that maintain product quality from receiving to shipping

- Lot and batch tracking systems that support recall management and compliance documentation

- Allergen segregation protocols that protect brands from cross-contamination risks

- Flexible space allocation that adapts to seasonal demand and promotional campaigns.

When a provider with deep food industry expertise manages storage, brands gain greater flexibility. Seasonal surges in demand, new product launches, and promotional campaigns no longer require scrambling for additional space or worrying about product spoilage. Inventory stays organized, accessible, and ready to ship when orders come in.

2. End-to-End Fulfillment for Multi-Channel Distribution

Restaurants and food brands today sell through multiple channels. A single product might ship directly to a consumer, go to a distributor in bulk, and appear on a grocery store shelf, all within the same week. Each channel has different packaging requirements, shipping methods, and compliance standards. Managing this internally creates chaos.

Restaurant logistics solutions designed for multi-channel distribution consolidate these workflows into a single operation. Direct-to-consumer orders get picked, packed, and shipped with branded packaging and tracking. Wholesale orders go out on pallets, with routing guides and advance shipping notices. Retail orders include barcoding, labeling, and case pack configurations required by big box stores.

This approach removes the need to use different systems or vendors for each sales channel. Brands get unified inventory visibility, streamlined order management, and consistent execution across every touchpoint. For QSR franchises, this means branded merchandise and promotional kits reach locations on time without diverting attention from daily operations. For specialty food makers, it means scaling into new retail accounts without having to rebuild internal processes.

The result is faster order turnaround, fewer errors, and the ability to grow revenue across multiple streams without increasing internal headcount or complexity.

3. Kitting and Custom Packaging Services

Meal kits, subscription boxes, promotional bundles, and seasonal gift packs all require assembly before they ship. This work is time-consuming, labor-intensive, and difficult to scale during peak periods. Many food businesses underestimate how much kitting slows down operations, only to be overwhelmed by it.

Professional restaurant logistics solutions include outsourced kitting and custom packaging services. Brands send individual components, and logistics teams assemble finished kits according to precise specifications. This includes branded packaging, inserts, labeling, and quality checks.

Common kitting use cases include:

- Meal kit assembly with recipe cards, portion-controlled ingredients, and branded packaging

- Retail multi-packs and variety bundles configured to buyer specifications

- Franchise promotional kits with seasonal merchandise and marketing materials

- Subscription box fulfillment with customized product selections and inserts

- Gift sets and holiday packages with custom wrapping and presentation.

For restaurants launching subscription programs or seasonal offerings, this flexibility is essential. Teams can test new products, adjust pack configurations, and respond to customer demand without investing in additional labor or floor space. Commissary kitchens that produce for multiple brands benefit from outsourcing assembly work while keeping production lines focused on food preparation.

Kitting also supports retail expansion. When grocery chains or club stores request custom multi-packs or display-ready configurations, brands need a partner who can execute quickly and accurately. Specialized providers handle this complexity while maintaining quality control and meeting tight deadlines.

4. Compliance and Routing Guide Management

Selling to retailers and distributors comes with strict requirements. Routing guides dictate how products must be packaged, labeled, and shipped. EDI systems require advance shipping notices and order confirmations. Mistakes result in chargebacks, delayed payments, and damaged relationships with buyers.

For restaurant brands entering retail or expanding wholesale channels, these compliance requirements are a significant barrier. In-house teams often lack the experience or systems to manage routing guides, pallet prep, and EDI integrations. This leads to costly errors and slow onboarding with new accounts.

Logistics providers with retail expertise take this burden off brands. They manage routing guide compliance, prepare pallets to buyer specifications, and handle EDI communications with major retailers and distributors. This ensures shipments arrive on time, meet buyer standards, and avoid costly penalties.

For QSR brands supplying franchise locations or regional distribution centers, this level of operational precision is just as important. Products flow smoothly through the supply chain, and teams avoid the hassle of manual tracking and coordination.

Compliance management also supports growth. When brands onboard new retail accounts or expand into additional regions, their logistics partner already has the systems and knowledge to execute without disruption.

5. Inventory Visibility and Reporting

Growing food businesses need accurate data to make decisions. How much inventory is on hand, what products are moving fastest, and when should the next production run happen? Without real-time visibility, brands operate on guesswork, which leads to stockouts, overstocking, and missed opportunities.

Logistics platforms today can integrate with eCommerce systems, ERPs, and retail partners to provide live inventory tracking. Brands can track inventory in real time, see what is currently in stock, monitor shipped orders, and view incoming inventory with complete visibility. Order status updates, exception alerts, and custom reporting dashboards give teams the clarity they need to stay proactive instead of reactive. Essential visibility features:

- Live inventory counts across all SKUs and lot numbers

- Automated reorder alerts based on customizable thresholds

- Order tracking with real-time status updates and exception notifications

- Sales trend analysis that supports production planning and forecasting

- Easy integration with existing business systems to ensure smooth data flow.

For commissary kitchens producing for multiple clients or restaurant groups managing branded products alongside in-store operations, this visibility prevents costly mistakes. Production schedules align with actual demand. Reorder points trigger automatically. Seasonal surges get managed without panic.

Moreover, real-time data supports better planning by enabling brands to analyze sales trends, forecast demand, and optimize inventory levels based on facts rather than assumptions. As a result, waste is reduced, cash flow improves, and the overall supply chain becomes more efficient.

Moving Forward with the Right Restaurant Logistics Solutions

As restaurants evolve into multi-channel food businesses, operational complexity increases. Internal teams often cannot manage storage, fulfillment, compliance, and reporting at scale.

Specialized restaurant logistics solutions provide the infrastructure needed to support growth while preserving product quality and brand consistency. With the right logistics partner, restaurant owners, commissary operators, and QSR brands gain the confidence to expand into new markets, launch new products, and meet customer demand wherever it appears.

Recommended Articles

We hope this guide on restaurant logistics solutions helps you streamline distribution and scale your food business with confidence. Explore these recommended articles for expert insights, practical strategies, and best practices to optimize fulfillment, compliance, and supply chain efficiency.