Introduction to Fiber Laser Cutting Machines

As the world pivots toward a decarbonized future, discussions often focus on policy changes and massive financial investments. The IEA reports global clean energy investment will hit $2 trillion in 2024, nearly double fossil fuel funding. However, beyond boardrooms and balance sheets, a significant transformation is taking place on the manufacturing floor. The “Green Grid” is more than a digital concept it is a vast physical infrastructure requiring millions of tons of precision-engineered steel, aluminum, and composite materials. To meet ambitious net-zero targets by 2030 and beyond, manufacturers have shifted from legacy fabrication methods to more advanced technologies. At the forefront of this transformation is the fiber laser cutting machine, a crucial tool for producing components that power the renewable energy revolution.

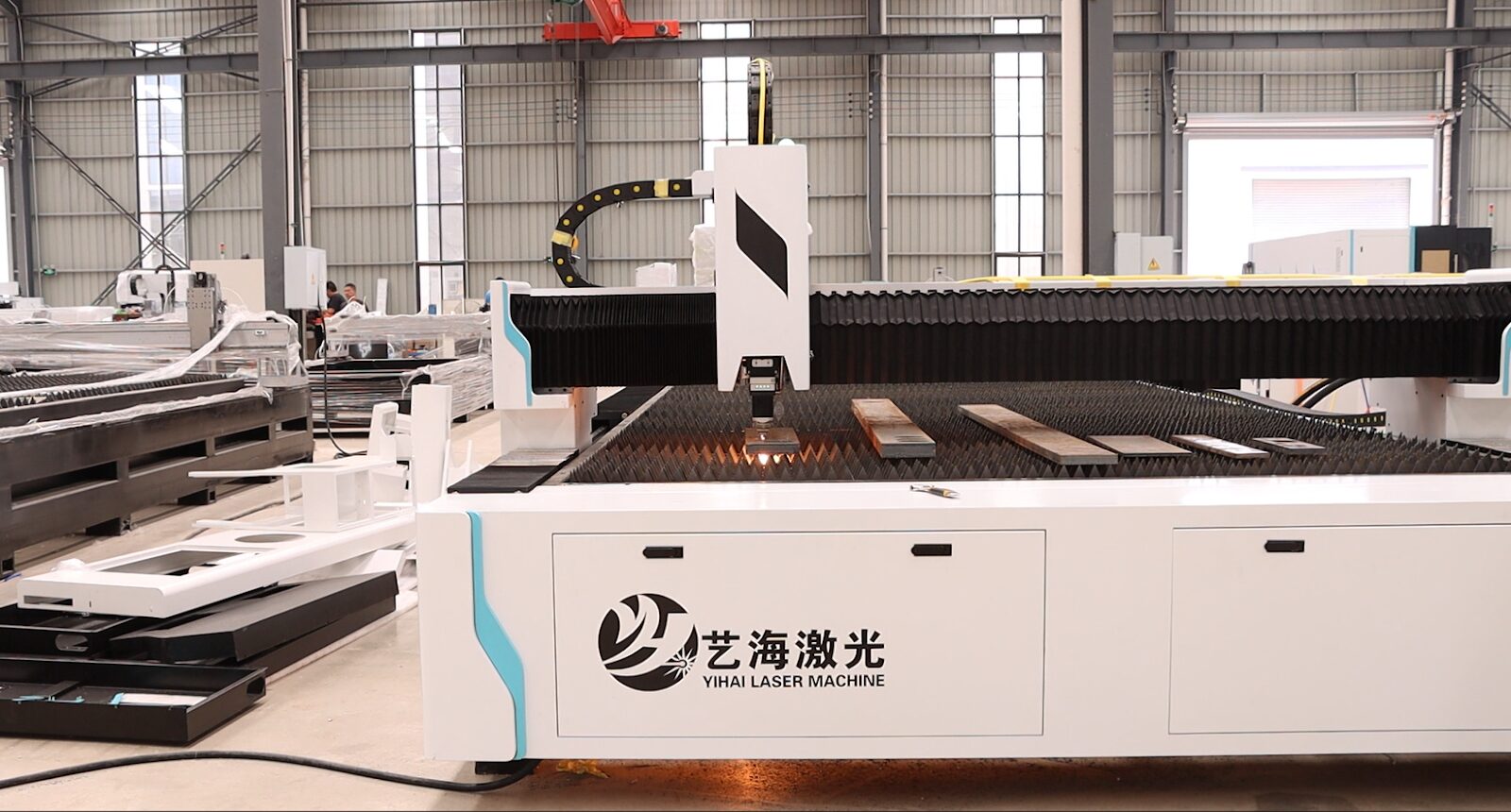

Image Source: Yihai Laser

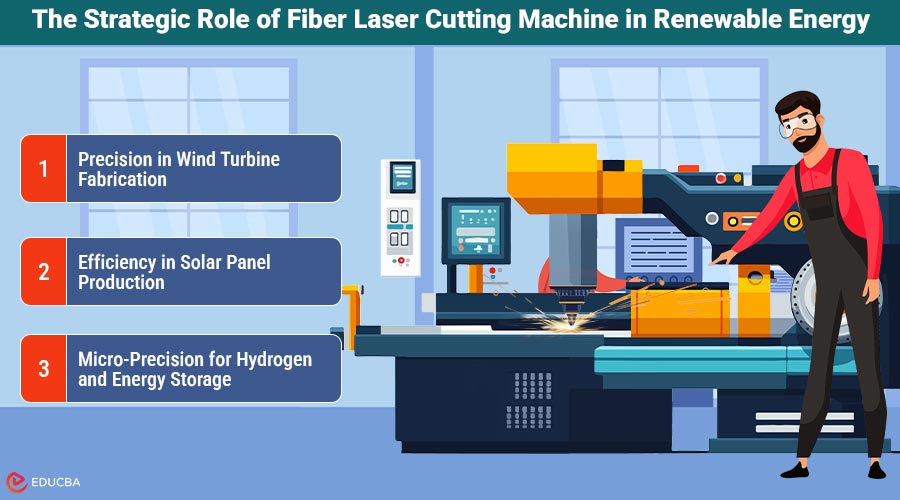

The Strategic Role of Fiber Laser Cutting Machine in Renewable Energy

The energy transition demands both extreme scale and extreme precision. The fiber laser cutting machine meets both needs and affects three key areas of renewable energy infrastructure.

1. Precision in Wind Turbine Fabrication

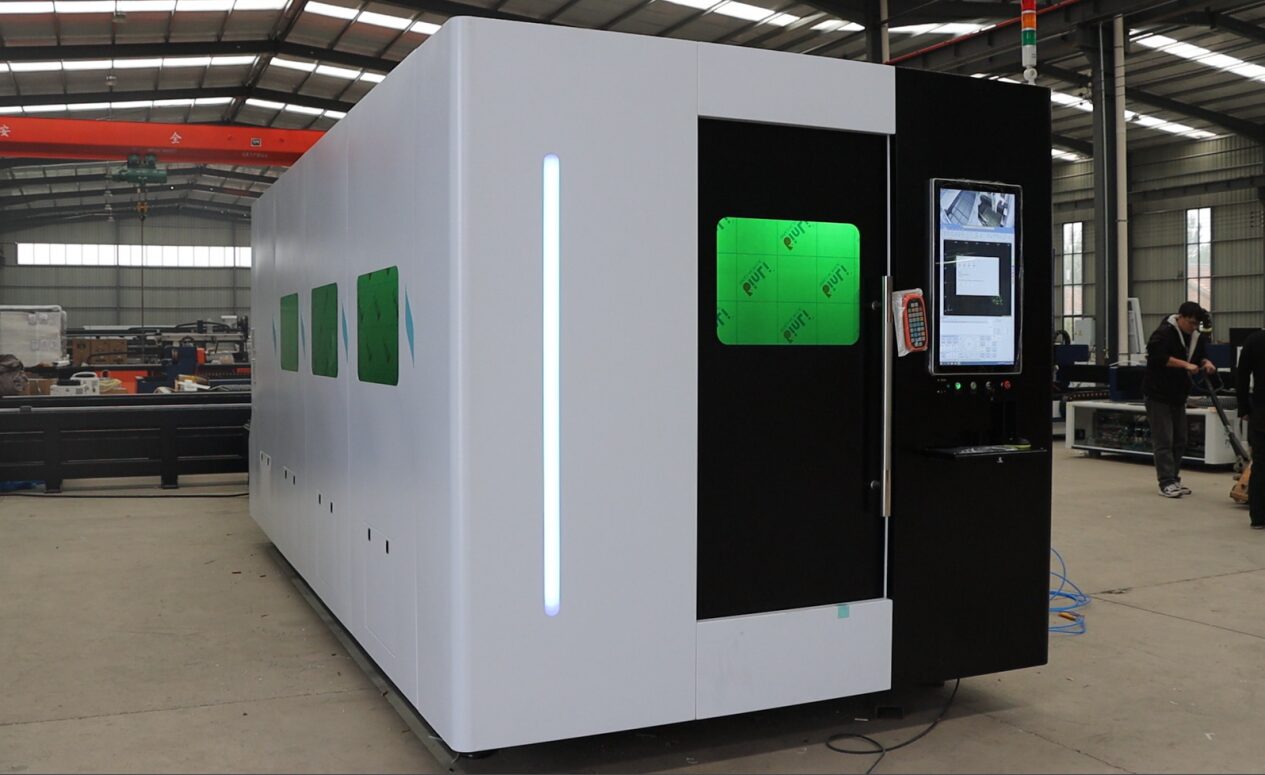

Image Source: Yihai Laser

Wind energy is perhaps the most visible symbol of the green transition. Offshore wind turbines are growing at an exponential rate, with some towers now reaching heights equivalent to 50-story skyscrapers. Fabricating these giants presents a unique challenge: how do you maintain structural integrity while processing massive, heavy-duty steel sections? Traditional plasma or mechanical cutting often struggles with the thickness and the “heat-affected zone” (HAZ). Excessive heat can compromise the edges, putting the structural integrity of the entire tower at risk. This is why the steel plate laser cutting machine has become the industry standard.

By using a concentrated, high-energy beam, a fiber laser cutting machine can slice through thick carbon steel with a level of precision previously unthinkable. The result is a clean, oxide-free edge that requires zero post-processing. In the world of wind energy, where every weld must withstand decades of salt spray and gale-force winds, this precision is not just about aesthetics it is about long-term reliability.

2. Efficiency in Solar Panel Production

Image Source: Yihai Laser

While wind energy deals with massive scale, solar energy is a game of volume. To power the global grid, hundreds of thousands of solar panels are installed every single day. Each of these panels requires a mounting frame, often made of galvanized steel or aluminum profiles, that is lightweight yet robust enough to withstand extreme weather for 25 years. In the solar sector, the priority shifts to throughput and repeatability. Here, laser fiber-cutting technology enables manufacturers to move from prototype to mass production in hours.

Unlike mechanical dies, which wear down and require expensive downtime for replacement, a laser system offers consistent performance across millions of cuts. Modern fabrication shops are now integrating their fiber laser cutting machine directly into automated assembly lines. This approach can cut production time by up to 50% compared to traditional methods. In massive industrial parks like those under construction in Arizona the ability to produce precision components quickly can determine whether a project stays on schedule or incurs multi-million-dollar delays.

3. Micro-Precision for Hydrogen and Energy Storage

Looking further ahead, the “Green Grid” will rely heavily on hydrogen fuel cells and advanced battery storage. This is where the question of “what is laser beam machining” becomes highly relevant to the C-suite. Unlike solar frames or wind towers, hydrogen components specifically bipolar plates require microscopic accuracy. In hydrogen technology, even a burr the size of a human hair can cause a catastrophic leak or loss of efficiency.

Laser beam machining (LBM) provides a non-contact solution that eliminates the mechanical stress associated with stamping. The precision of high-end laser cutting systems enables the creation of intricate flow channels in ultra-thin stainless steel or titanium foils. This level of detail is impossible with conventional tools. It is the silent “digital chisel” of the energy transition, enabling engineers to design more efficient fuel cells that require less space and generate more power.

The Economics of the “Green” Machine

Image Source: Yihai Laser

Critics often cite the initial capital expenditure for high-tech machinery as a barrier. However, the B2B reality is that the ROI (Return on Investment) of a fiber laser cutting machine is superior due to several factors that align with modern ESG (Environmental, Social, and Governance) goals:

- Energy Efficiency: A fiber laser is significantly more energy-efficient than older CO2 variants, converting a higher percentage of electricity into actual cutting power.

- Zero-Waste Capability: The narrow kerf (cut width) of a laser enables tighter part nesting. This maximizes material utilization, significantly reducing scrap metal sent to landfills.

- Labor Resilience: In an era of skilled labor shortages, a user-friendly, automated laser system enables a single technician to oversee multiple machines, maintaining high-volume output without a massive workforce.

Final Thoughts

The transition to a sustainable energy system is often framed as a software or policy challenge. Still, its success depends on hardware: the millions of precision parts that form turbines, panels, and fuel cells. The fiber laser cutting machine is not a mere manufacturing convenience it is a foundational technology that delivers the precision, speed, and efficiency required to build the Green Grid at scale. For industrial leaders and infrastructure developers, investing in laser-based fabrication is less about chasing novelty and more about securing the longevity, performance, and economics of the renewable assets that will power the coming decades.

Recommended Articles

We hope this guide on fiber laser cutting machines helps you understand their role in renewable energy manufacturing. Check out these recommended articles for more insights and practical strategies.