What is Robotics Automation?

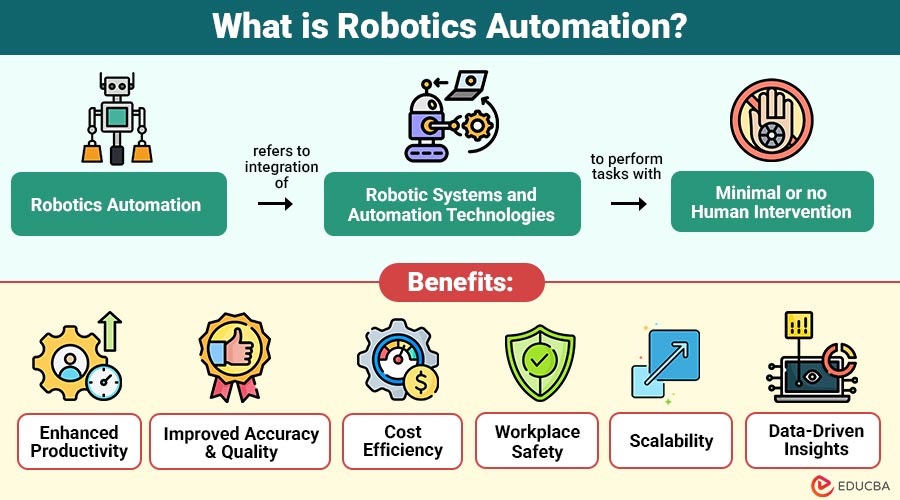

Robotics Automation refers to the integration of robotic systems and automation technologies to perform tasks with minimal or no human intervention. It involves the use of programmable machines—robots—that can carry out complex or repetitive activities autonomously or semi-autonomously.

Table of Contents:

Key Takeaways:

- Robotics automation enhances productivity by performing repetitive tasks efficiently while consistently minimizing human errors.

- Integration of AI and sensors enables robots to adapt, learn, and optimize complex operational processes.

- Long-term savings, improved quality, and workplace safety benefits offset high initial costs.

- Robotics reshapes industries, creating new technical roles while demanding reskilling and ethical consideration for implementation.

Key Components of Robotics Automation

Here are the essential key components that make up a robotics automation system:

1. Robots

These are the core physical machines designed to execute tasks. Robots can range from simple robotic arms used in factories to complex humanoid robots or autonomous drones.

2. Sensors

Sensors collect data from the environment (e.g., proximity, temperature, pressure, or vision) and allow the robot to make informed decisions and react in real-time.

3. Actuators

Actuators convert electrical signals into physical movement, enabling robots to perform actions such as gripping, lifting, or moving.

4. Controllers

Controllers serve as the robot’s “brains,” analyzing information, carrying out commands, and coordinating motions.

5. Software and Algorithms

Software enables the programming and automation of robotic tasks. With AI and machine learning algorithms, robots can learn, adapt, and optimize performance over time.

6. Connectivity and Integration

Integration with other systems (such as the Internet of Things, cloud computing, or enterprise software) enhances automation, data sharing, and decision-making.

Types of Robotics Automation

Robotics automation can be categorized based on application and level of autonomy:

1. Industrial Robotics

Used in manufacturing and production lines, these robots handle tasks like welding, painting, and assembly with precision and speed.

2. Service Robotics

These robots assist humans in performing services such as healthcare support, cleaning, or hospitality tasks.

3. Collaborative Robots

Cobots work alongside humans in shared workspaces, offering flexibility and safety while improving productivity.

4. Autonomous Mobile Robots

These robots navigate independently using sensors and AI, commonly found in logistics, warehousing, and delivery services.

5. Process Automation Robots

Also known as Robotic Process Automation (RPA), these software robots automate repetitive digital tasks such as data entry, billing, and reporting.

How Robotics Automation Works?

The process of robotics automation involves several stages:

1. Task Identification

Identify repetitive, hazardous, or time-consuming tasks suitable for automation to enhance productivity, safety, and operational efficiency across processes.

2. System Design

Engineers create a customized robotic system by selecting suitable hardware, sensors, actuators, and control software to perform desired operations effectively.

3. Programming

Robots are programmed using algorithms or AI-based learning models to follow predefined instructions, adapt to conditions, and optimize task performance.

4. Integration

The robotic system is connected to existing enterprise software, IoT devices, and workflows for seamless communication and coordinated operational efficiency.

5. Operation and Optimization

Deployed robots gather real-time data, analyze performance, and use machine learning to improve precision, efficiency, and adaptability in tasks continuously.

Applications of Robotics Automation Across Industries

Here are some key applications of robotics automation in various sectors:

1. Manufacturing

Robotics automation has long been the backbone of the manufacturing industry. Robots perform welding, painting, and assembly with speed and precision, ensuring consistent product quality and reducing downtime.

2. Agriculture

Robotics automation in agriculture includes automated tractors, crop monitoring drones, and harvesting robots that increase productivity and reduce labor dependency.

3. Construction

Robots are used for bricklaying, 3D printing of structures, and site inspections, improving efficiency and worker safety.

4. Retail

Automated checkout systems, inventory robots, and smart warehouses streamline retail operations and enhance customer experience.

5. Defense and Security

Robots are used for surveillance, bomb disposal, reconnaissance, and border security, reducing risk to human personnel.

Benefits of Robotics Automation

Here are the benefits that robotics automation brings to businesses and industries:

1. Enhanced Productivity

Robots can operate continuously without fatigue, working 24/7, significantly increasing overall operational efficiency and reducing production bottlenecks.

2. Improved Accuracy and Quality

Automation reduces human errors, maintaining consistent output quality, precision, and reliability, which ensures superior products and customer satisfaction.

3. Cost Efficiency

While initial setup costs are high, long-term savings come from reduced labor, minimized errors, and optimized operational efficiency.

4. Workplace Safety

Robots perform hazardous or repetitive tasks, minimizing workplace accidents, protecting employees, and creating a safer industrial environment.

5. Scalability

Robotic systems can be easily scaled or reprogrammed to accommodate increased production, product variety, or changing operational demands.

6. Data-Driven Insights

Robotics collects detailed performance and process data, enabling better decision-making, continuous optimization, and improved operational strategies.

Challenges in Robotics Automation

Here are some of the key challenges faced when implementing robotics automation:

1. High Initial Investment

The cost of robots, maintenance, and system integration can be prohibitive for small businesses.

2. Job Displacement Concerns

Automation may replace certain repetitive or manual jobs, leading to workforce displacement if reskilling initiatives are lacking.

3. Technical Complexity

Implementing and maintaining robotic systems requires specialized knowledge and ongoing technical support.

4. Cybersecurity Risks

Robots are susceptible to cyber threats that could interfere with operations as they are linked to networks.

5. Ethical and Regulatory Issues

The use of robots in sensitive areas like healthcare or defense raises ethical and legal questions.

6. Integration with Legacy Systems

Difficulty in seamlessly connecting robots with outdated machinery or software can hinder efficiency and increase implementation costs.

Final Thoughts

Robotics Automation stands as one of the most transformative forces of the 21st century. By merging mechanical precision with artificial intelligence, it is not only redefining productivity but also reshaping how humans interact with technology. While challenges like cost, ethics, and job displacement remain, the benefits—efficiency, safety, and innovation—far outweigh the drawbacks. In a rapidly changing digital landscape, embracing robotics automation is no longer an option—it is a necessity for businesses that aim to stay efficient, agile, and future-ready.

Frequently Asked Questions (FAQs)

Q1. How is robotics automation different from traditional automation?

Answer: Traditional automation relies on fixed systems with limited flexibility, while robotics automation uses intelligent, programmable machines that can adapt, learn, and make decisions based on data.

Q2. What is the impact of robotics automation on employment?

Answer: While robotics automation may replace certain manual roles, it also creates new opportunities in the robot maintenance, AI development, system design, and data management. Reskilling and education are key to adapting to this shift.

Q3. How does AI enhance robotics automation?

Answer: AI allows robots to analyze data, recognize patterns, make decisions, and continuously improve performance—transforming them from simple mechanical tools into intelligent systems.

Recommended Articles

We hope that this EDUCBA information on “Robotics Automation” was beneficial to you. You can view EDUCBA’s recommended articles for more information.