What is Reshoring?

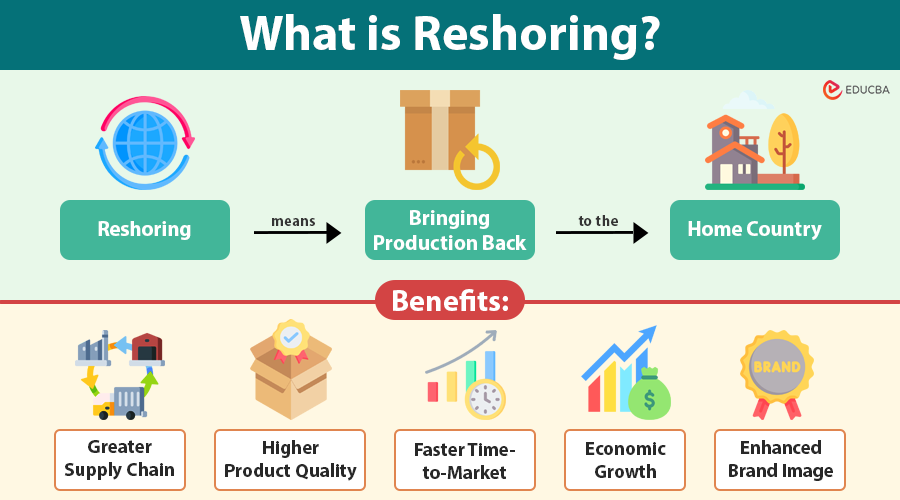

Reshoring is the process by which a company brings its manufacturing, production, or business operations back to its home country after previously moving them overseas. It is the opposite of offshoring and aims to improve supply chain reliability, product quality, and operational control.

A U.S.-based electronics company had moved its circuit board production to China to reduce labor costs. However, after facing long shipping delays, rising overseas wages, and quality issues, the company decided to shift its production back to the United States. It invested in automation and partnered with local suppliers to make domestic manufacturing cost-effective. This move helped the company achieve faster delivery, better quality control, and reduced supply chain risks, a practical example of reshoring in action.

Table of Contents

- Meaning

- Reasons

- Benefits

- Challenges

- Reshoring vs. Offshoring vs. Nearshoring

- Key Industries

- Implementation

- Future

Key Takeaways

- Reshoring strengthens supply chain reliability by reducing dependence on distant, risk-prone global networks.

- Automation and advanced technologies make domestic manufacturing more efficient and cost-effective.

- Rising overseas labor costs and geopolitical tensions are major drivers pushing companies to bring production home.

- Reshoring improves quality control and speeds up time-to-market due to proximity to production.

- Industries like electronics, automotive, pharmaceuticals, and defense are leading the reshoring movement as part of long-term strategic planning.

Why Are Companies Reshoring?

Organizations are reshoring for several strategic and operational reasons:

1. Supply Chain Disruptions

Global events from pandemics to port congestion, geopolitical tensions, and transportation delays have exposed the fragility of long, complex supply chains. Companies now prefer shorter, more reliable networks that reduce risk and improve stability.

2. Rising Overseas Labor Costs

Countries once known for low-cost labor are experiencing rising wages, stricter compliance requirements, and increasing operational challenges. As a result, the cost advantage of offshoring is slowly narrowing.

3. Advancements in Automation

Advanced technologies such as robotics, AI, and intelligent manufacturing systems reduce the need for manual labor. These advancements enable companies to run highly efficient domestic production lines while maintaining competitive costs.

4. Improved Quality Control

Keeping production closer to home allows businesses to enforce strict quality standards, reduce defect rates, and respond quickly to manufacturing issues. This proximity improves oversight and strengthens product consistency.

5. Government Incentives

Many governments actively encourage reshoring initiatives by offering tax credits, subsidies, grants, and supportive industrial policies. These incentives make domestic manufacturing more financially attractive and sustainable.

Benefits of Reshoring

Reshoring offers long-term advantages that strengthen both companies and national economies:

1. Greater Supply Chain Resilience

Shorter, localized supply chains reduce exposure to global disruptions, transportation delays, and geopolitical uncertainty. Companies gain stability and control over critical operations.

2. Higher Product Quality

Proximity to production facilities enables tighter oversight and quicker corrective actions. This approach ensures consistent quality, fewer defects, and better adherence to regulatory standards.

3. Faster Time-to-Market

Domestically produced goods reach customers more quickly because companies eliminate long shipping routes and logistical bottlenecks. This speed gives businesses a competitive advantage in fast-moving markets.

4. Economic Growth and Job Creation

Reshoring revitalizes local industries by increasing manufacturing activity, creating skilled jobs, and boosting regional economic development. It strengthens national industrial capabilities and reduces dependence on foreign production.

5. Enhanced Brand Image

Consumers increasingly value locally made, ethically produced, and sustainable products. Reshoring helps companies build trust, improve brand reputation, and appeal to environmentally and socially conscious buyers.

Challenges of Reshoring

Despite its advantages, reshoring requires careful planning, investment, and long-term commitment. Companies often face the following challenges:

1. Higher Domestic Labor Costs

Wages, labor regulations, and compliance requirements in home countries can significantly increase operating expenses compared to low-cost offshore locations.

2. Infrastructure Requirements

Organizations may need to build new facilities, upgrade outdated plants, or invest in advanced manufacturing technologies. These infrastructure demands require time, capital, and strategic planning.

3. Skill Gaps in the Workforce

Modern manufacturing depends on specialized skills in automation, robotics, and digital production. Many regions struggle with shortages of trained technicians and engineers, slowing the reshoring process.

4. High Transition Costs

Relocating operations involves major expenses, including equipment transportation, reinstallation, facility shutdowns abroad, and local setup costs. These financial burdens can delay implementation.

5. Limited Local Supplier Networks

Some industries lack robust domestic supply chains or vendor ecosystems. Companies may need time to identify, develop, or train local suppliers, which can slow early production stages.

Reshoring vs Offshoring vs Nearshoring: Key Differences

To clearly understand how reshoring compares with offshoring and nearshoring, the table below highlights the distinctions based on cost, location, control, and supply chain impact:

| Parameter | Reshoring | Offshoring | Nearshoring |

| Definition | Bringing production back to the home country | Moving production to a distant foreign country | Moving production to a nearby/neighboring country |

| Primary Goal | Improve control, stability, & quality | Lower production costs | Balance cost reduction with geographical proximity |

| Cost Impact | Improve control, stability, & quality | Lower production costs | Moderate labor cost & low transport cost |

| Supply Chain Risk | Low (local supply chain) | High (distance, geopolitical risk) | Moderate (regional stability) |

| Lead Time | Fastest | Slowest | Shorter than offshoring |

| Quality Control | Strongest due to proximity | Moderate, depends on oversight | Better than offshoring |

| Communication Barriers | Minimal | High (time zones, language) | Low to moderate |

| Best For | High-quality, advanced manufacturing | Large-scale low-cost production | Faster delivery at moderate cost |

| Examples | Manufacturing returning to US, EU, India | China, Vietnam, Bangladesh | US–Mexico & EU–Eastern Europe partnerships |

Industries Driving the Reshoring Movement

Several industry sectors, especially those requiring advanced technology, strict quality control, and secure supply chains, are at the forefront of reshoring initiatives. These include:

- Electronics & Semiconductors: Chip shortages and geopolitical risks are pushing manufacturers to bring production closer to home.

- Automotive & Electric Vehicles (EVs): EV batteries, motors, and other critical components benefit from local manufacturing to accelerate innovation and meet stringent quality standards.

- Pharmaceuticals & Medical Devices: Ensuring the supply of essential drugs and medical tools has become a priority, making domestic production more attractive.

- Aerospace & Defense: National security concerns make local manufacturing critical for sensitive components.

- Consumer Durables & Appliances: Demand for faster delivery and higher quality drives companies to relaunch domestic factories.

- Textiles & Apparel: Brands increasingly prefer on-shore production for sustainable practices, reduced lead times, and ethical manufacturing.

How Companies Can Implement Reshoring Successfully?

To execute reshoring efficiently, companies follow structured, strategic steps that balance cost, technology, and workforce readiness:

1. Invest in Automation & Industry 4.0

Advanced robotics, IoT systems, and AI-powered analytics enhance productivity and reduce reliance on manual labor—making local manufacturing more cost-effective.

2. Develop Local Supplier Ecosystems

Collaborating with domestic suppliers, logistics partners, and raw material vendors reduces reliance on imports and strengthens the regional industrial base.

3. Leverage Government Incentives

Many governments offer tax benefits, subsidies, simplified regulations, and production-linked incentives to support reshoring initiatives.

4. Reskill and Upskill the Workforce

Training programs in robotics, digital manufacturing, CNC machining, and data-driven operations prepare the workforce for modern production requirements.

5. Adopt Flexible and Lean Production Models

Lean systems, modular layouts, and scalable production lines enable companies to adjust quickly to market fluctuations while keeping costs under control.

The Future of Reshoring

- Reshoring is shifting from a cost-driven choice to a strategic priority for global businesses.

- Increasing geopolitical tensions, supply chain disruptions, and global uncertainties are pushing companies to relocate production closer to home.

- Advancements in automation, AI, robotics, and smart factories make domestic manufacturing more efficient and competitive.

- Governments worldwide are encouraging reshoring through tax benefits, financial incentives, infrastructure support, and pro-manufacturing policies.

- Consumers now prefer locally produced, ethical, and sustainable products, increasing demand for domestic production.

- Reshoring enhances supply chain transparency, improves quality control, and reduces dependency on global intermediaries.

- The movement is reshaping global manufacturing models, driving innovation, and strengthening national economies.

- Overall, reshoring is not a temporary phase; it is transforming how companies design supply chains and operate worldwide.

Final Thoughts

Reshoring is no longer just a response to rising costs or global disruptions; it has become a strategic move for companies seeking stronger supply chains, better quality control, and long-term stability. With advancements in automation and increased government support, domestic production is now more feasible and competitive than ever.

Although reshoring comes with challenges such as higher labor costs and the need for skilled talent, its long-term benefits outweigh the hurdles. Companies that invest in modern technologies, build local supplier networks, and strengthen workforce capabilities will be well-positioned to thrive in an unpredictable global environment.

Frequently Asked Questions (FAQ’s)

Q1. Is reshoring only relevant for large corporations?

Answer: No. Small and medium-sized businesses are also reshoring to improve quality, reduce logistics costs, and respond more quickly to customer needs.

Q2. Is reshoring more expensive than offshoring?

Answer: Initially, it can be more expensive due to higher labor and setup costs. However, long-term savings come from fewer disruptions, lower shipping costs, and improved quality control.

Q3. How long does a typical reshoring project take?

Answer: A reshoring transition generally takes 6 months to 3 years, depending on facility readiness, supply chain development, regulatory requirements, and workforce availability.

Q4. Can reshoring help reduce geopolitical risks?

Answer: Yes. By moving production closer to home, companies reduce exposure to trade conflicts, political instability, import restrictions, and global transport delays.

Q5. Do automation and Industry 4.0 make reshoring more viable?

Answer: Absolutely. Technologies such as robotics, AI, and smart factories reduce operational costs and enable companies to run efficient domestic production lines.

Recommended Articles

We hope this comprehensive guide on Reshoring helps you understand how companies are transforming their manufacturing and supply chain strategies. Explore related articles on Global Supply Chain Management, Manufacturing Trends, and Operational Efficiency Strategies to expand your knowledge and stay updated on the future of production and logistics.