Introduction to Materials Management

Materials are the lifeblood of any organization. Without raw materials, production halts. Without spare parts, machinery downtime increases. Without finished goods, customers remain unsatisfied. This is where Materials Management plays a pivotal role.

It is not just about ordering and storing items; it involves strategic planning, efficient utilization, and timely movement of materials across different functions. The goal is to ensure that the right material of the right quality is available at the right place, in the right quantity, and at the right time, all while keeping costs under control.

In the competitive world, companies are under immense pressure to cut costs, minimize waste, and improve operational efficiency. Proper materials management ensures:

- Lower production costs by optimizing procurement.

- Reduction in idle time due to the non-availability of raw materials.

- Smoother workflow in manufacturing and service delivery.

- Higher profitability and customer satisfaction.

Table of Contents

- Introduction

- Meaning

- Objectives

- Functions

- Importance

- Examples

- Best Practices

- Challenges

- Materials Management vs. Inventory Management

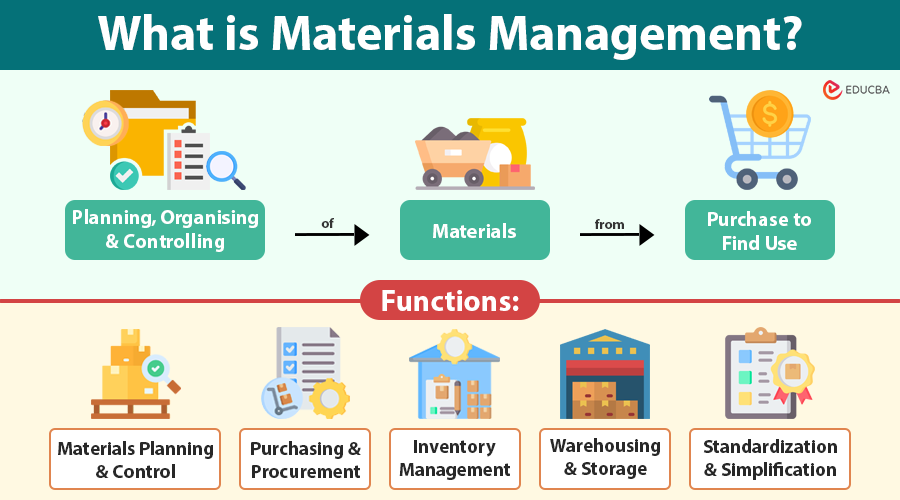

What is Materials Management?

Materials Management is defined as a systematic process of planning, organizing, controlling, and coordinating the flow of materials from the initial purchase to their final consumption. It includes raw materials, semi-finished goods, consumables, spare parts, packaging, and even scrap.

It is a comprehensive approach that connects multiple business areas:

- Procurement & purchasing: Finding reliable suppliers at competitive prices.

- Inventory control: Maintaining the right balance between shortage and surplus.

- Warehousing & storage: Ensuring safety and accessibility of materials.

- Production support: Providing materials exactly when needed.

- Logistics & distribution: Handling inbound and outbound material flow.

For example, in an automobile company, materials management ensures a steady supply of steel, rubber, and electronic parts. A delay in any one of these can disrupt the entire production line, resulting in financial losses.

Objectives of Materials Management

The ultimate goal of materials management is to strike a balance between cost efficiency and uninterrupted production. Below are the key objectives explained in detail.

1. Continuous Supply of Materials

A main objective is to keep raw materials, components, and consumables available at all times so production runs without interruptions. A steady flow of materials enables organizations to fulfill customer orders on time. For instance, in the FMCG industry, packaging materials must always be available in sufficient quantities, as even a small delay can disrupt dispatch schedules and impact customer satisfaction.

2. Cost Optimization

Another important objective is to reduce overall costs related to materials. This involves effective vendor negotiation to bring down purchase costs, minimizing expenses associated with storage, handling, and insurance, and making use of bulk purchases whenever feasible to lower per-unit costs. Cost efficiency achieved at the procurement and storage stages directly enhances the organization’s profitability.

3. Quality Assurance

It also focuses on ensuring that only the right quality of materials enters the production cycle. When materials meet specified quality standards, they contribute to producing reliable end products. Conversely, poor-quality inputs can lead to defects, rework, wastage of resources, and dissatisfied customers. Hence, maintaining strict quality control in procurement is central to this objective.

4. Efficient Inventory Control

Inventory management forms an integral part of materials management. The objective here is to maintain a balance between under-stocking and overstocking. Managers widely use techniques such as Economic Order Quantity (EOQ), ABC Analysis, and Just-in-Time (JIT) to manage stock levels effectively. The right control system ensures that production continues smoothly without incurring unnecessary costs due to excess inventory.

5. Minimization of Waste

A well-structured materials management system minimizes losses arising from pilferage, obsolescence, or damage. This is particularly relevant when dealing with perishable or sensitive raw materials that require careful handling and storage. For example, storing perishable food ingredients in cold storage facilities helps avoid spoilage and wastage, thereby preserving both resources and profits.

6. Strong Supplier Relations

Another key objective is to build and maintain strong relationships with suppliers. Long-term partnerships with reliable vendors lead to consistent supply, competitive pricing, favorable credit terms, and opportunities for innovation. Supplier collaboration is not limited to transactional exchanges but often extends to co-developing solutions that improve overall efficiency.

7. Productivity and Profitability

Ultimately, materials management plays a crucial role in enhancing productivity and profitability. By ensuring the right materials are available at the right time, organizations can maximize the use of their workforce and machinery. Smooth workflows lead to faster production cycles, better customer service, and enhanced profitability.

Functions of Materials Management

Materials management ensures that an organization plans, acquires, stores, and utilizes its materials in the most efficient way possible through a wide range of interrelated activities. Each function is important for keeping the supply chain smooth and using resources effectively.

1. Materials Planning and Control

The first function involves planning material requirements in line with production schedules. This includes forecasting demand using past consumption data and market trends, along with implementing tools such as Material Requirement Planning (MRP). Effective planning helps in preventing both stockouts and excess purchases, ensuring that material availability is always in sync with operational needs.

2. Purchasing and Procurement

Another vital function is the process of purchasing and procurement. This involves selecting reliable suppliers after careful evaluation of quality, price, and delivery capabilities. It also includes negotiating contracts, tenders, and long-term agreements. Many organizations adopt strategies such as global sourcing to reduce costs and enhance competitiveness by accessing broader supplier networks.

3. Inventory Management

Efficient inventory management ensures that stock levels are maintained at optimal levels, thereby preventing waste and shortages. Managers achieve this by using techniques such as Economic Order Quantity (EOQ), safety stock planning, and reorder level analysis. More advanced methods such as ABC, VED, and FSN analyses are also widely used. For example, critical medical supplies like oxygen cylinders are categorized under VED—Vital, Essential, and Desirable—to prioritize availability.

4. Warehousing and Storage

Safe and systematic storage of materials is another essential function of materials management. Proper warehousing involves not only physical facilities but also the adoption of methods such as First-In-First-Out (FIFO) or Last-In-First-Out (LIFO), depending on the nature of the product. In modern operations, automation, barcoding, and warehouse management systems are used to improve efficiency and reduce errors.

5. Standardization and Simplification

This function involves reducing the number of material varieties to simplify procurement and handling. By following international standards such as ISO, organizations maintain consistency and reliability in their material quality. For instance, using standardized sizes of nuts and bolts across different machinery reduces complexity, improves interchangeability, and streamlines procurement.

6. Logistics and Distribution

The logistics function ensures the smooth movement of materials, both inbound (raw materials arriving at the factory) and outbound (finished goods delivered to customers). It includes coordination with transport providers, scheduling deliveries, and using logistics software for real-time tracking. Efficient logistics enhances customer satisfaction and reduces transportation costs.

7. Disposal of Surplus and Scrap

It also addresses the proper disposal of surplus and scrap materials. Identifying obsolete, damaged, or excess stock and handling it responsibly helps reduce financial losses. This function also emphasizes sustainability by encouraging recycling, resale, or eco-friendly disposal methods, which not only save money but also support corporate social responsibility initiatives.

Importance of Materials Management

The significance of materials management goes far beyond cost savings. It impacts the entire organization:

- Cost reduction: Lowers purchase, warehousing, and wastage costs.

- Operational efficiency: Ensures uninterrupted production, reducing downtime.

- Improved product quality: Better inputs lead to better outputs.

- Customer satisfaction: Ensures on-time delivery of finished goods.

- Better resource utilization: Optimizes manpower, machinery, and capital.

- Strategic advantage: Well-managed materials provide a competitive edge in pricing and delivery speed.

Examples of Materials Management

1. Manufacturing Industry

In automobile manufacturing, materials management ensures a steady supply of essential components such as steel, tires, and electronic parts. By coordinating procurement, inventory, and warehousing, manufacturers prevent production delays caused by shortages.

For example, Toyota’s Just-in-Time (JIT) system delivers parts exactly when they are needed, which lowers storage costs and improves efficiency.

2. Healthcare Industry

Hospitals and clinics rely heavily on materials management to maintain critical medical supplies like medicines, surgical instruments, and protective equipment. Efficient tracking, storage, and timely replenishment help avoid stockouts, ensuring uninterrupted patient care.

For example, a well-managed hospital pharmacy uses automated inventory systems to monitor expiration dates and reorder levels.

3. Construction Industry

Construction projects require materials like cement, steel, sand, and bricks to be available at the right time. Proper materials management ensures timely delivery to construction sites, reducing delays and preventing cost overruns.

For example, large-scale infrastructure projects often use centralized procurement and logistics tracking systems to coordinate supplies across multiple sites.

4. Retail Industry

Retail chains manage large volumes of inventory across multiple stores and warehouses. Materials management helps maintain optimal stock levels, reducing overstocking or stockouts.

For example, supermarkets use real-time inventory software to track product movement, enabling timely replenishment and minimizing waste.

5. Food & Beverage Industry

Food processing companies rely on materials management to handle perishable raw materials like fruits, grains, and dairy products. Proper storage, timely procurement, and FIFO inventory methods help maintain freshness and prevent spoilage.

For example, a beverage company may use cold storage facilities and automated tracking to manage ingredient quality and supply continuity.

Best Practices in Materials Management

Companies can adopt these practices for maximum efficiency:

1. Technology Integration

- Use ERP systems (like SAP, Oracle, Microsoft Dynamics) for real-time data.

- Employ IoT sensors and AI-driven analytics for predictive inventory control.

2. Just-in-Time (JIT) Inventory

- Reduces inventory carrying costs.

- Organizations order materials only when they require them in the production cycle.

3. Vendor Development & Supplier Partnerships

- Engage in long-term contracts with trusted suppliers.

- Implement Vendor-Managed Inventory (VMI) systems.

4. Lean Manufacturing Principles

- Eliminate unnecessary movement, storage, and waste.

- Streamline production processes for faster turnaround.

5. Regular Audits & Cycle Counts

- Physical stock verification to ensure system accuracy.

- Identifies pilferage, theft, or system errors early.

6. Workforce Training

- Managers train employees in handling materials, safety, and storage.

- Promotes accountability and efficiency.

Challenges in Materials Management

Despite its importance, companies face several challenges:

- Uncertain demand forecasting: Rapid market changes make predictions difficult.

- Global supply chain risks: Political instability, strikes, or pandemics disrupt supply.

- Inventory holding costs: High rent, insurance, and capital blockage.

- Supplier issues: Delays, poor quality, or dependency on single vendors.

- Obsolescence of materials: Especially in fast-moving industries like electronics.

- Lack of skilled workforce: Improper handling leads to wastage and inefficiency.

Materials Management vs. Inventory Management

| Aspect | Materials Management | Inventory Management |

| Scope | Broader, includes procurement, planning, storage, logistics | Narrower, focuses mainly on stock control |

| Focus | Ensuring the right materials at the right time and cost | Maintaining the right stock levels |

| Integration | Covers entire supply chain activities | Subset of materials management |

| Example | Managing raw materials, spare parts, and logistics | Tracking available stock of raw materials |

Final Thoughts

In conclusion, Materials Management is the backbone of efficient business operations. By ensuring uninterrupted material flow, minimizing wastage, and maintaining cost efficiency, it directly influences profitability and customer satisfaction.

Organizations that invest in technology-driven materials management systems are better equipped to handle global uncertainties, reduce costs, and improve supply chain resilience. Whether in manufacturing, construction, retail, or healthcare, effective materials management is a strategic necessity.

Frequently Asked Questions (FAQs)

Q1. What are the skills required for a career in materials management?

Answer: Professionals in materials management require strong analytical skills, effective negotiation abilities, knowledge of procurement processes, and expertise in inventory control systems. Familiarity with ERP software, logistics coordination, and supplier relationship management is also essential.

Q2. What industries rely heavily on materials management?

Answer: Almost all industries benefit from materials management, but it is especially vital in manufacturing, construction, automotive, retail, and healthcare. For example, hospitals rely on effective materials management to maintain critical supplies like medicines and surgical instruments.

Q3. How can poor materials management affect a company’s reputation?

Answer: Ineffective materials management can lead to frequent delays, product shortages, or the delivery of substandard goods to customers. Over time, this reduces customer trust, damages the brand’s reputation, and can result in a loss of market share.

Q4. What role does sustainability play in materials management?

Answer: Sustainability has become a major focus in modern materials management. Companies now emphasize reducing waste, recycling scrap materials, sourcing eco-friendly raw materials, and implementing green logistics to minimize their environmental footprint.

Recommended Articles

We hope this guide to materials management was helpful. Explore our related articles on supply chain optimization, inventory control techniques, and procurement strategies to strengthen your business operations.