Introduction to Commercial Greenhouse

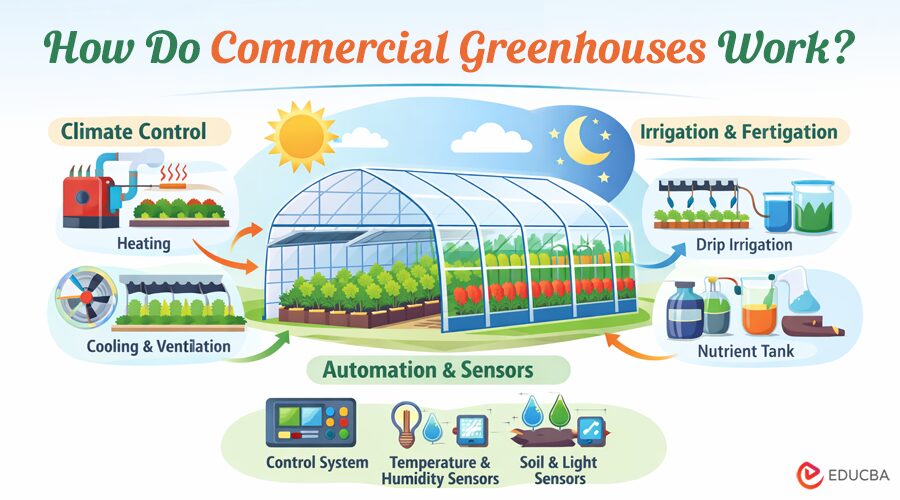

A commercial greenhouse is not a “big plant room.” If you want to strip it down to its core, it is a production environment. Moreover, the goals of that environment are steady crop timing, predictable yield, and uniform quality. That only happens when you control what plants respond to most light, temperature, humidity, and nutrition while keeping costs in check.

What makes a commercial greenhouse different from a hobby setup is the level of intentionality in the systems. Instead of reacting when plants start looking stressed, growers manage conditions, so stress is less likely to happen in the first place.

Let us explore how a commercial greenhouse works in more detail.

How Commercial Greenhouse Structure Shapes Light and Heat?

The greenhouse shell decides how much sunlight enters, how much heat stays inside, and how quickly conditions swing when the weather changes. With this in mind, glazing choice matters because it affects light transmission and insulation. Glass often provides strong light and durability. At the same time, plastics like polycarbonate or film can be cost-effective and easier to install, but come with trade-offs in heat retention and lifespan.

Inside a commercial greenhouse, growers use shading systems and thermal curtains to fine-tune conditions. Shading reduces heat load and light intensity during peak sun hours. Thermal curtains help retain heat at night and reduce energy loss, improving overall efficiency.

Temperature Control for Predictable Growth

If you had to pick one variable that most directly affects growth speed, it would be temperature. Commercial greenhouses heat because they need plants to keep moving even when nights are cold, or winter arrives. Boilers, unit heaters, and hot-water piping systems are common, and the strategy typically aims for stable “day” and “night” targets that match the crop and growth stage.

Cooling is the tougher problem in many climates because you are fighting solar gain in a sealed structure. Ventilation handles much of it through roof vents, side vents, and fans that move hot air out and bring in outside air. There is also evaporative cooling (such as wet walls or fogging), which can lower the incoming air temperature by using water evaporation. However, this also affects humidity, which can create other challenges if you are not careful.

Some greenhouse cooling approaches rely on deeper thermodynamic principles, especially when pressure and energy changes are involved. According to Cold Shot Chillers, “Adiabatic cooling operates on the principles of thermodynamics where energy (heat) is transferred from one medium to another as ‘work’ without an actual exchange of mass. The adiabatic cooling process occurs when a reduction in the pressure within a system causes a volume expansion, resulting in ‘work’ on the surrounding environment.”

Growers do not need to know thermodynamics in detail, but the equipment in a commercial greenhouse operates on basic physical principles. Growers must remove heat effectively, and the method they choose affects humidity levels, airflow, and overall plant health.

The Role of Irrigation And Fertilization

At a commercial scale, watering is not something you do only when it looks dry. It is measured and scheduled. Drip lines, ebb-and-flow benches, hydroponic channels, misting, and other systems deliver water in controlled amounts to achieve uniform moisture across the crop. Uniformity is a big deal because plants that receive slightly different water levels can grow at different rates, and that creates grading headaches at harvest.

Many operations combine watering with feeding via a process known as fertigation. Growers mix nutrients into the irrigation water and adjust the formula based on the crop type, its growth stage, and environmental conditions. That is why you will see growers pay close attention to pH and EC. Small drifts can change uptake, slow growth, and show up later as quality issues you cannot “fix” quickly.

Sensors And Automation

Commercial greenhouses do not run well on intuition alone, especially when you are managing multiple zones and tight schedules. Sensors track temperature, humidity, light levels, CO2, and moisture in the root zone. Controls then trigger all the fans, vents, heating, irrigation, and shading we have discussed thus far within set ranges.

It is important to point out that automation does not replace skilled growers. It merely supports them and comes alongside what they are already doing. You still need people who can spot early signs of stress and adjust targets when conditions change. However, automation keeps the system from relying on constant manual corrections, reducing the risk of inconsistency.

Final Thoughts

A commercial greenhouse succeeds when environmental conditions remain stable enough for plants to grow consistently every day. That stability comes from balancing linked variables. Moreover, when you manage these relationships with clear targets and reliable equipment, the greenhouse becomes a place where life thrives.

If you want to understand how it works, do not get distracted by advanced gadgets. Focus on the fundamentals and go from there.

Recommended Articles

We hope this guide on commercial greenhouse systems helps you better understand controlled crop production and environmental management. Explore these recommended articles for deeper insights, practical strategies, and expert growing tips.